Location: Gujarat, India

Digital Maintenance Logbooks

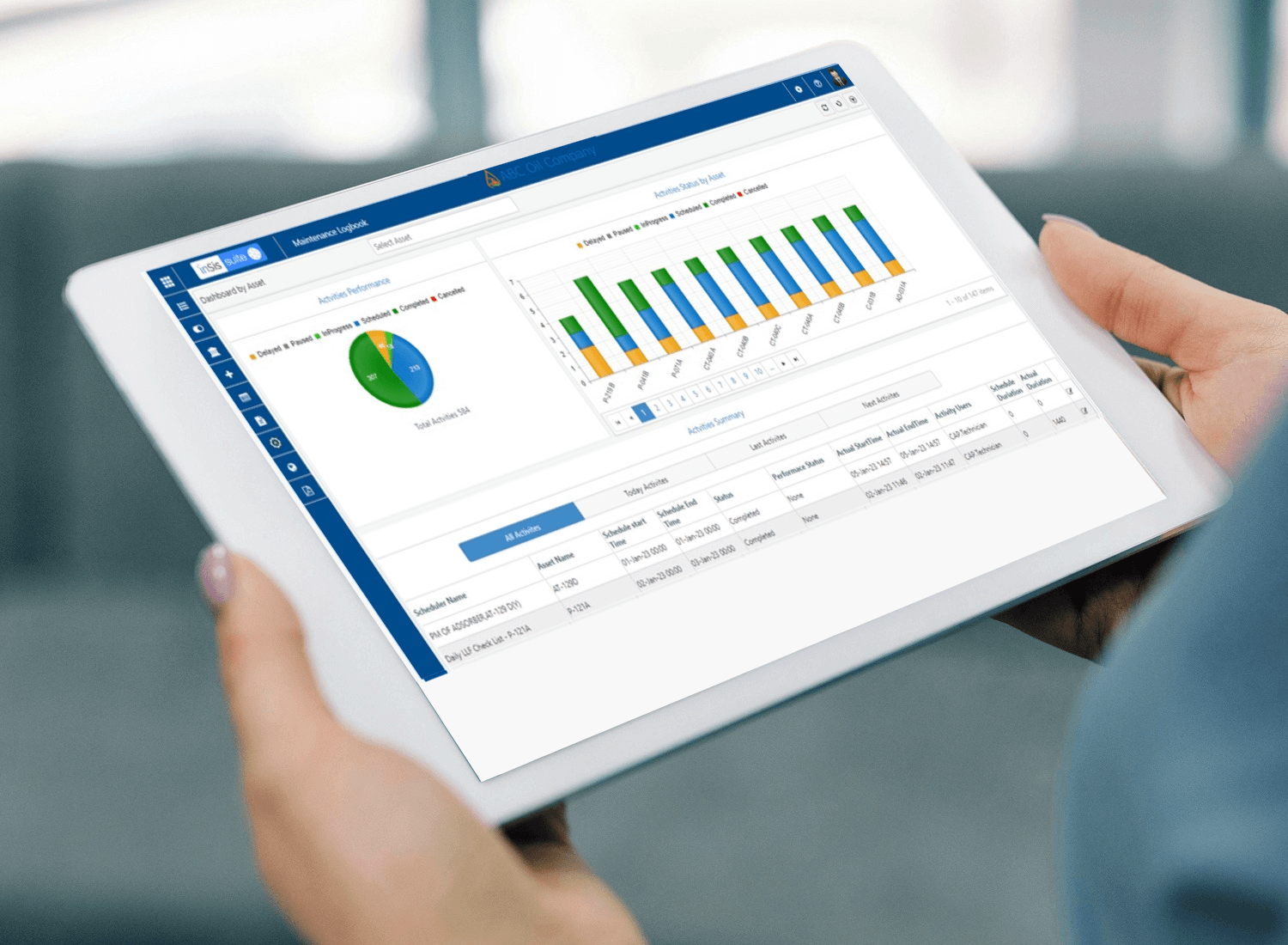

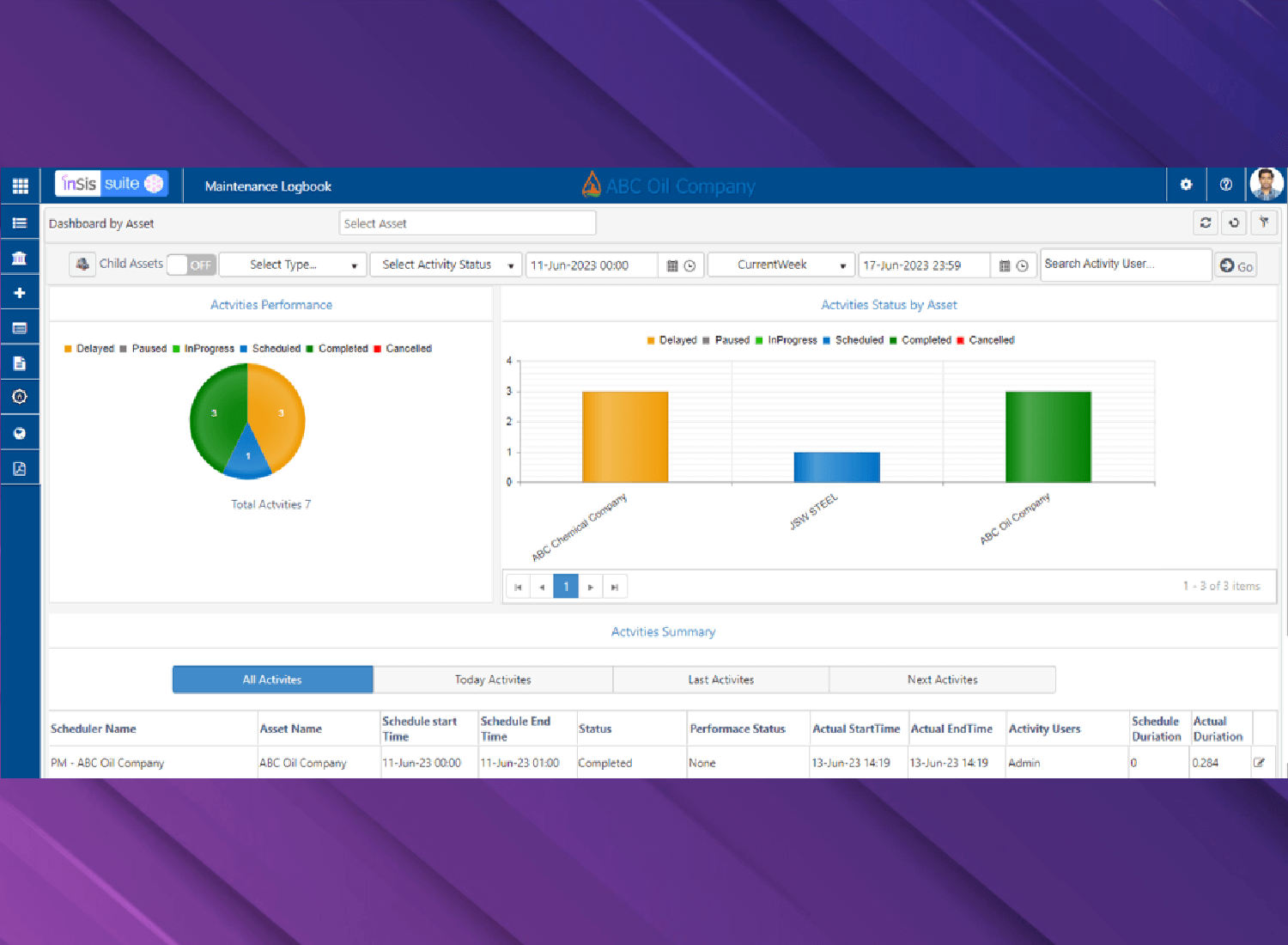

Real-time data views, effective decisions

Solution benefits

By using our digital maintenance logbooks, you will appreciate the importance of having a comprehensive platform to capture end-to-end plant data.

Savings in data handling & analytics time

Accurate and timely reports

Pay-back period

How this helps your operations

Industrial project

Installing digital logbooks in VSF business

This system replaced 10 paper logbooks and 5 manual checklists with our digital solution, boosting efficiency and reducing errors. Preventive maintenance schedules were automatically synced from SAP through RFCs, ensuring all assets are serviced according to plan. Automated reports keep top management informed with key maintenance data delivered directly to their emails.

QR code enabled checklists further simplify the process for technicians. Most importantly, the system automated preventive maintenance compliance tracking, maximizing asset availability and reliability across the entire operation. This translated to fewer equipment failures, smoother operations, and ultimately, a sharper competitive edge.

Core features

The InSis Digital Maintenance Logbooks ensure seamless integration of asset information and PM schedule.

- Easy integration of asset information and schedules through RFCs

- Easy access to assets with reduced downtime, improved OEE, and timely interventions

- Integrates with SAP PM Module, Process Historian, and other systems

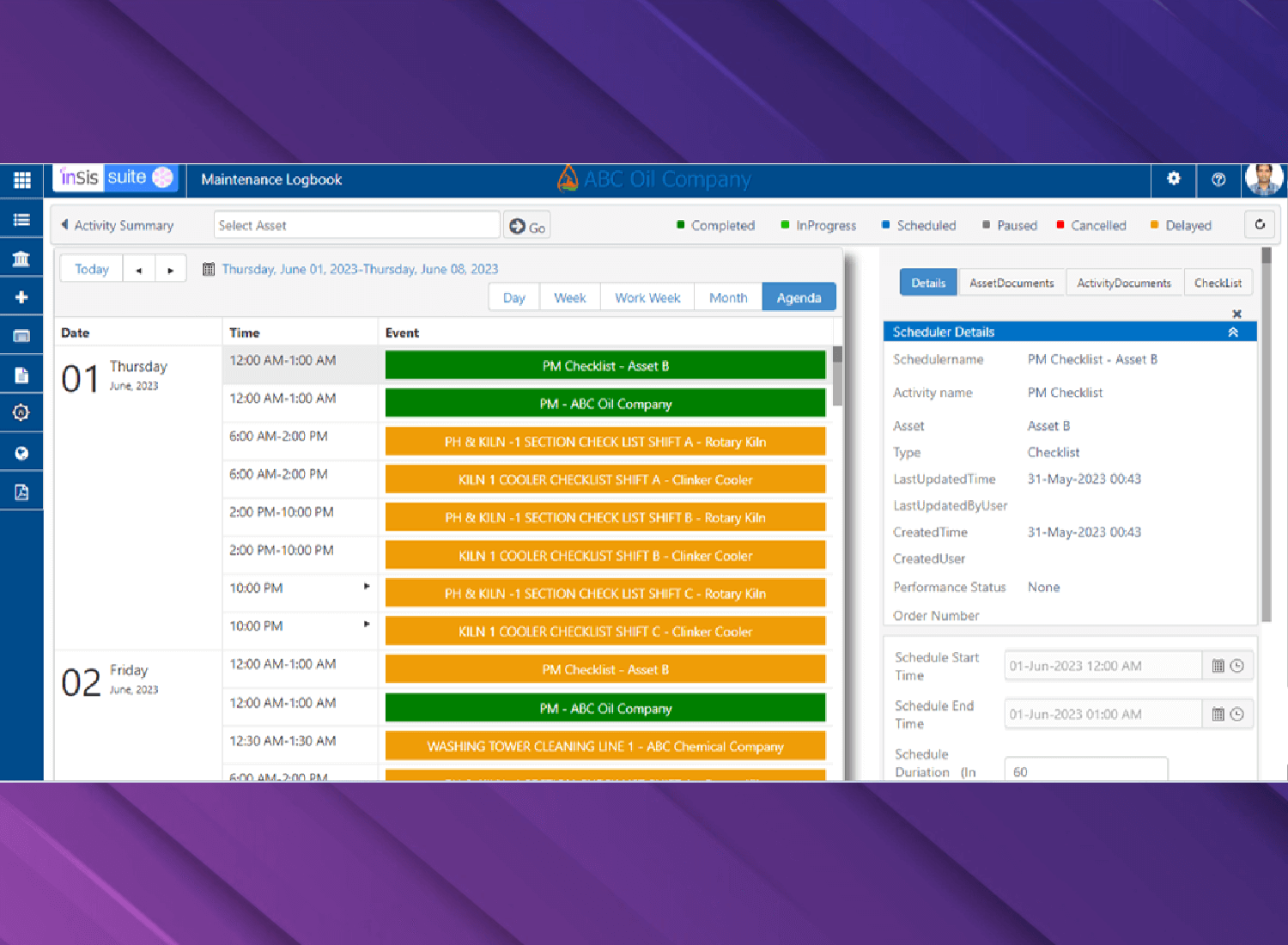

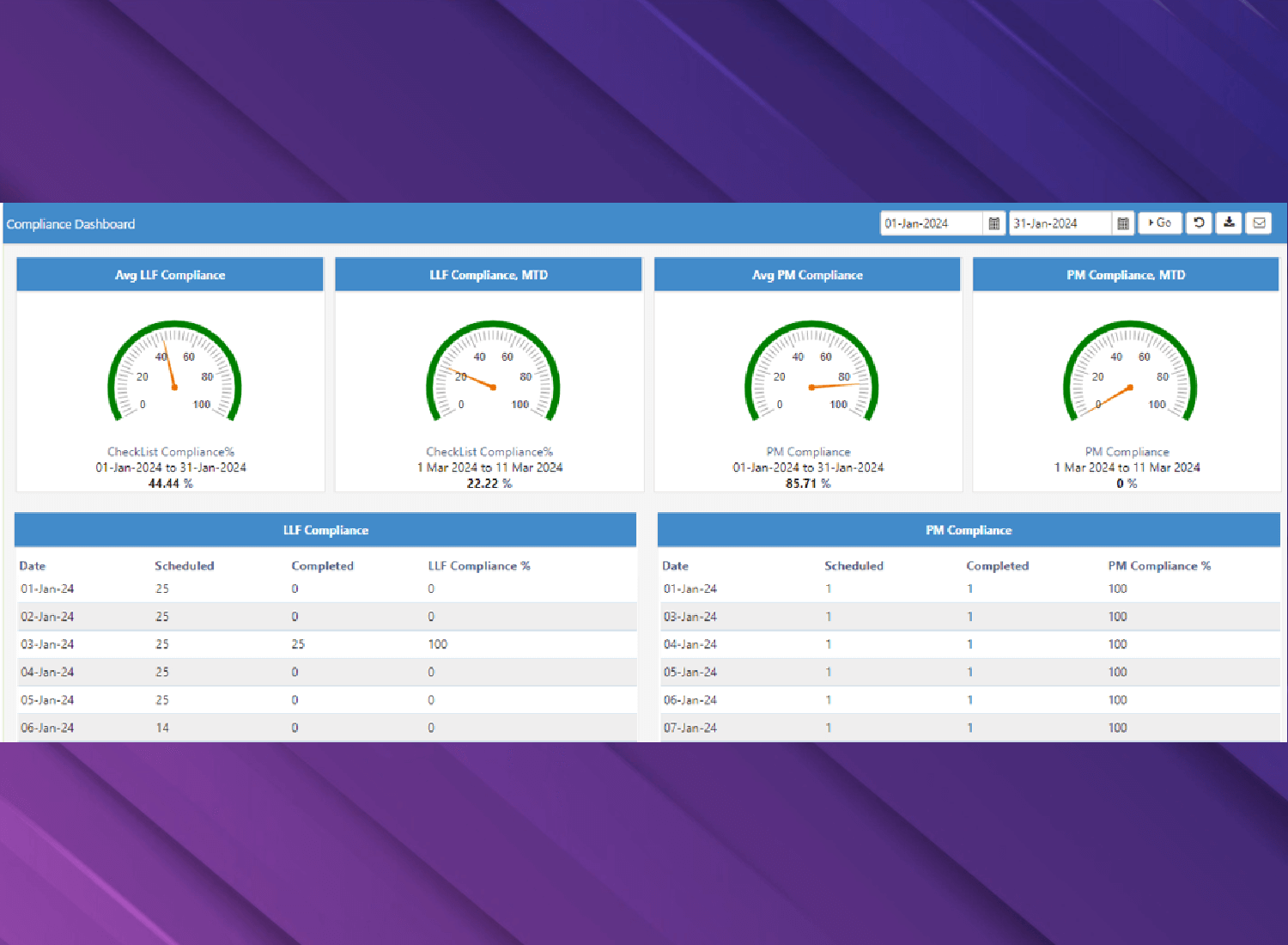

The Digital Maintenance Logbooks drive compliance to PM schedule through automated reports and deviation reports.

- Data visualization and analytics provide real-time and historical data

- QR-based asset scanning to drive compliance of site visit to each asset

- Thorough and detailed maintenance checks

This solution allows logbooks and checklists to be configured for each asset.

- Centralized asset information for all maintenance teams to collaborate and improve asset life

- Re-usable checklist templates are available for quick customization

- Asset analysis can be done in conjunction with process data for an end-to-end assessment

The InSis Digital Maintenance Logbooks ensure automation of equipment history card, outage report and abnormality report for easy collaboration.

- Accessibility on mobile and associated analytics provides flexibility to operators

- Collaborative as all instructions are seen by concerned team members

The Digital Maintenance Logbooks provide historical data and analytics for taking data-based decisions.

- Simple visualizations and associated analytics aid in the decision-making process

- Asset data and process data is seen in unison for contextual analysis

- Timely actions ensure improved asset life

How it works

The digital maintenance logbooks work on multiple modes, including online, offline, and auto modes. If network is not available at the field, offline mode can be used (data from handheld devices can be synced up once the network is available). Logbook data can be integrated with DCS/historian/SAP/LIMS/MES data. Use of 4G/5G requires a secure domain configuration.

The maintenance logbook can be accessed in four easy steps. In the first step, the Project Manager (PM) should login with QR code. In the second step, all the checklists would be visible. In the third step, the PM can open the required checklist. In the final step, the PM can enter status/comments.

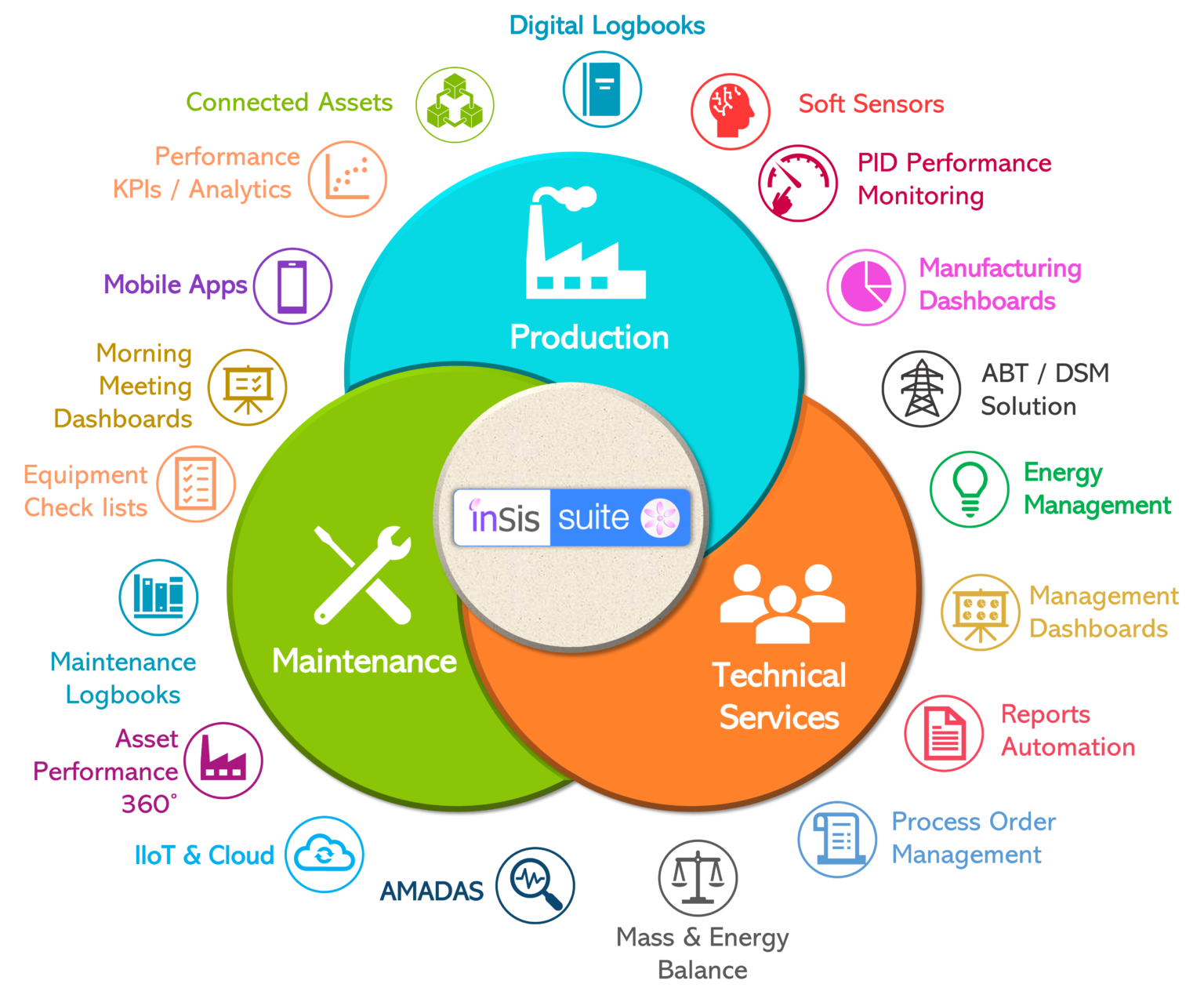

A modular solution

Resources

Deployment of Digital Maintenance Logbooks in a Viscose Staple Fibre Unit

This system replaced 10 paper logbooks and 5 manual checklists with our digital solution, boosting

Comprehensive Management of Online Analysers for a Refinery through ABB

The key challenge faced was the real-time monitoring and calibration of online analyzers and data