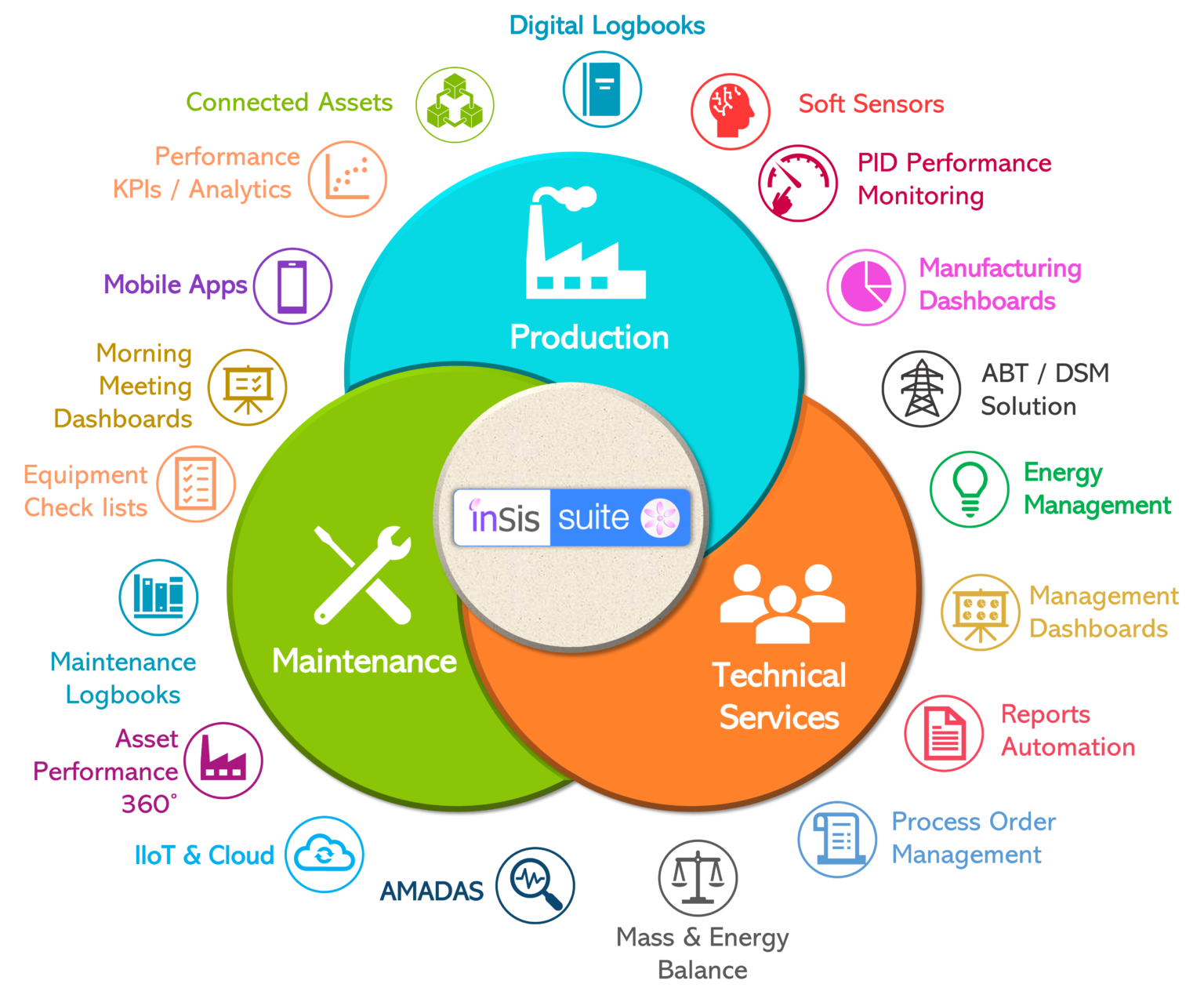

Integration through RFCs

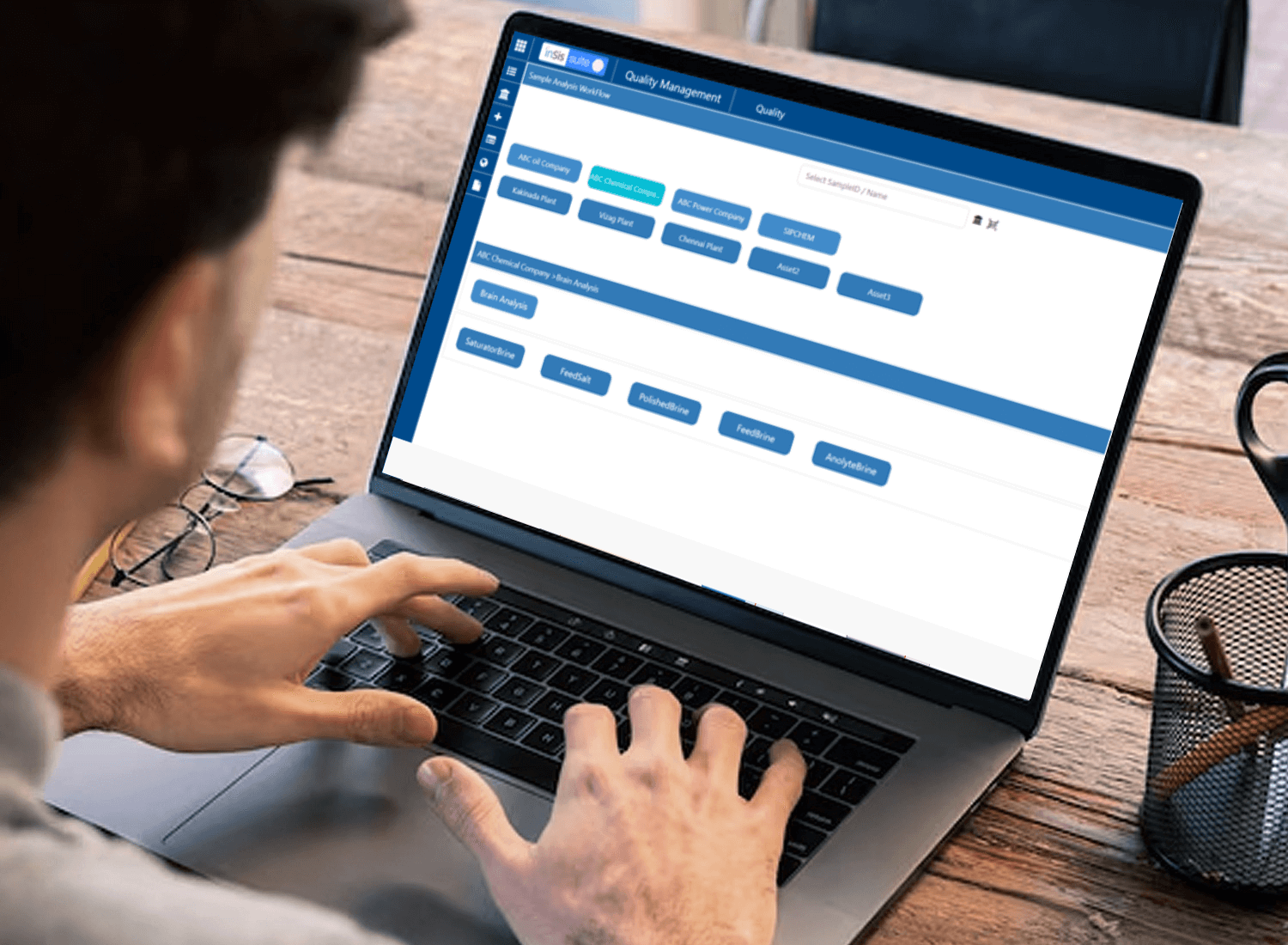

Laboratory Information Management

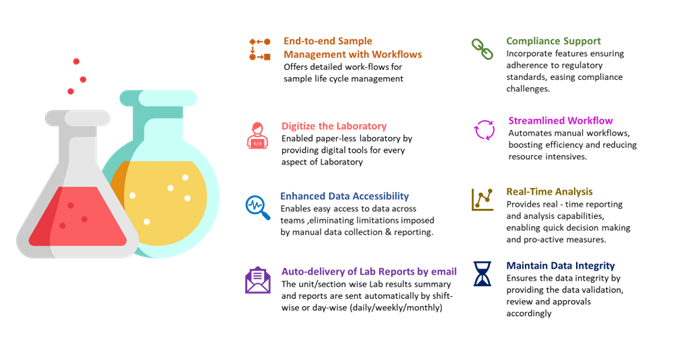

Digitize your laboratory, automate processes

Solution benefits

LIMS enhances your lab performance, reduces errors and ensures compliance with industry standards. It provides online availability of laboratory inventory and sample information, supports paperless labs and reduces the need for paper documentation.

Savings in operator’s time

Pay-back period

Real-time

Online data for decision-making

How this helps your operations

Core features

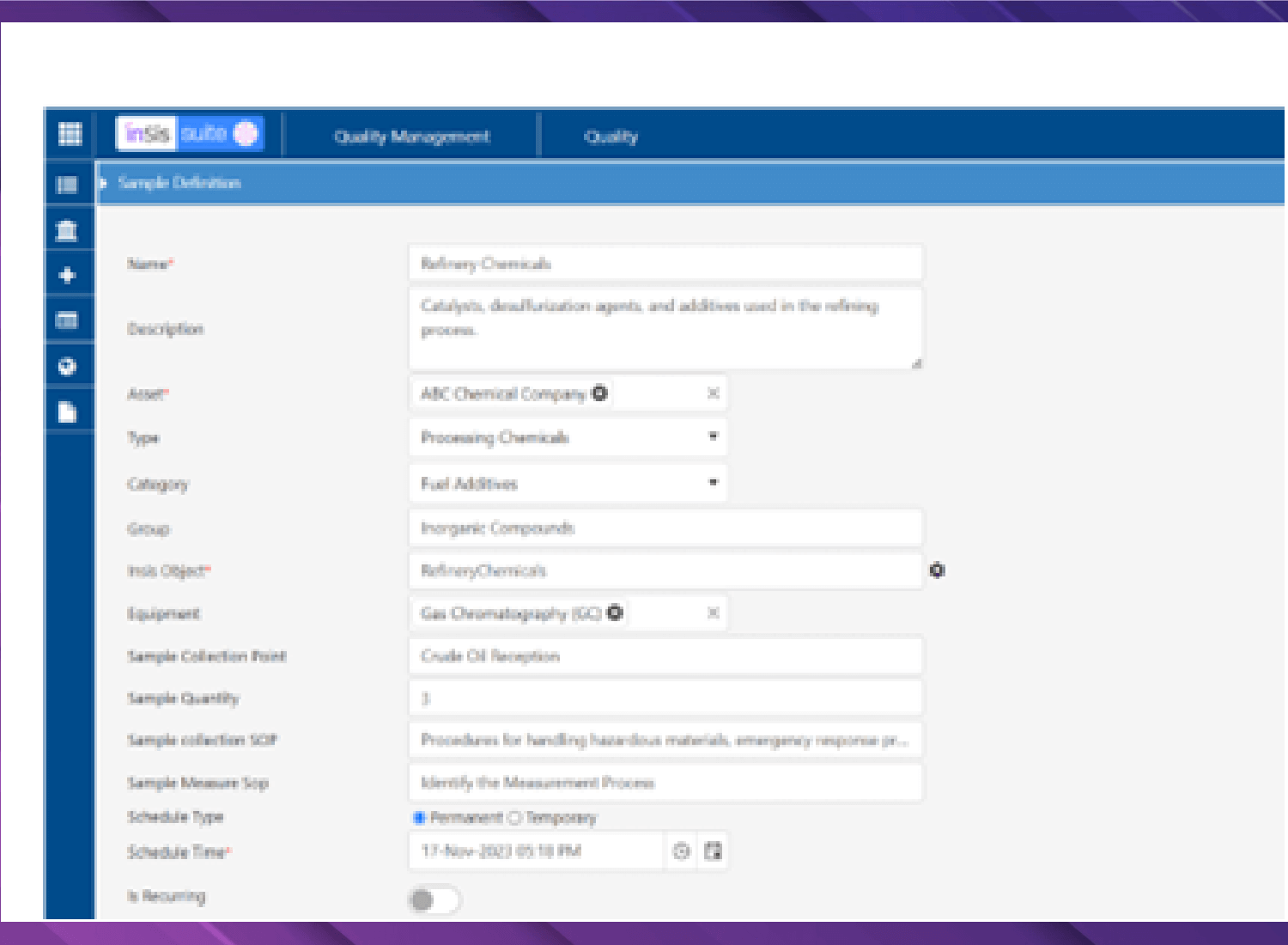

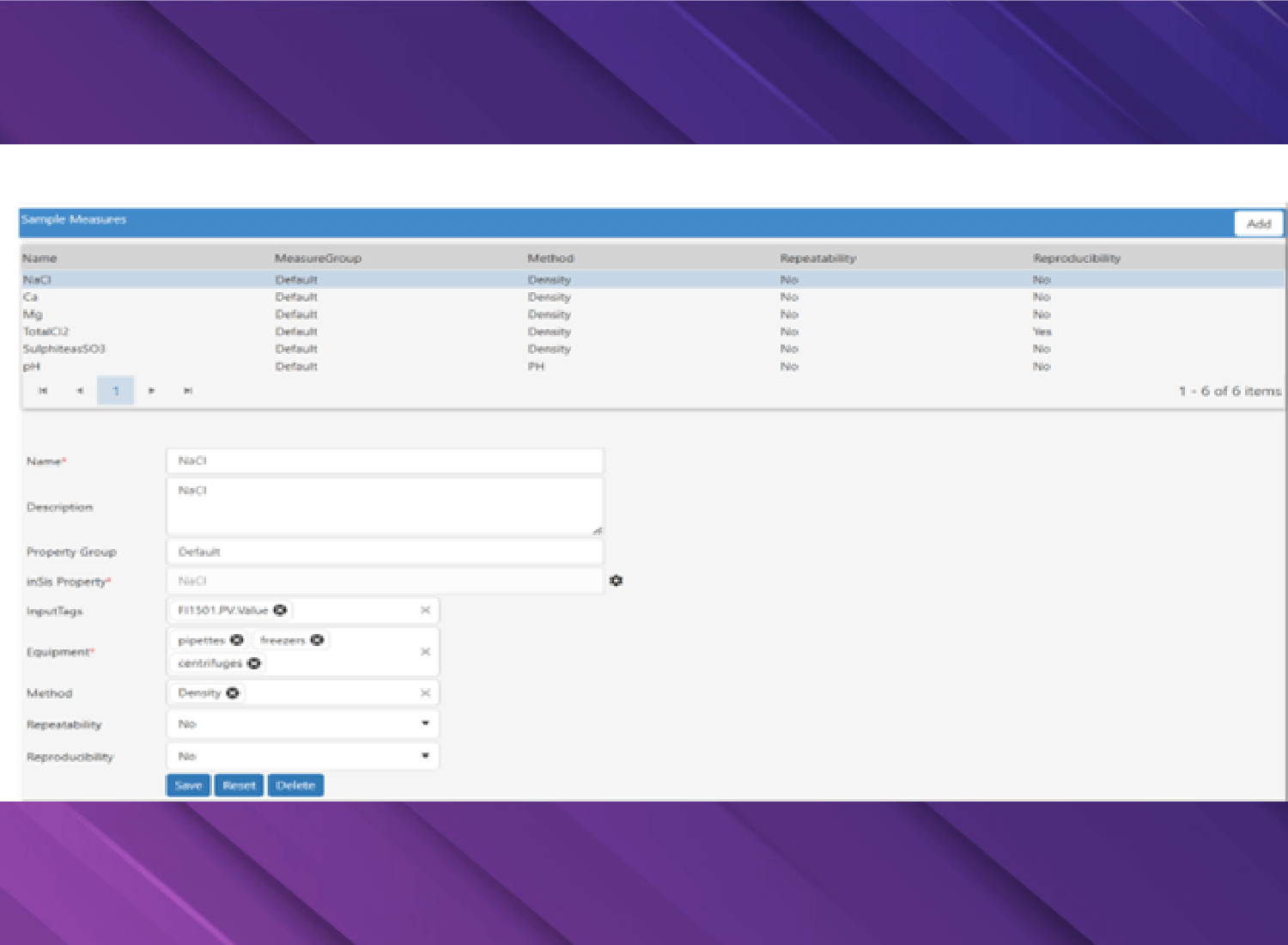

- Register new samples efficiently

- Capture essential information: quantity, retention time, SOPs, metadata

- Track samples from receipt to analysis

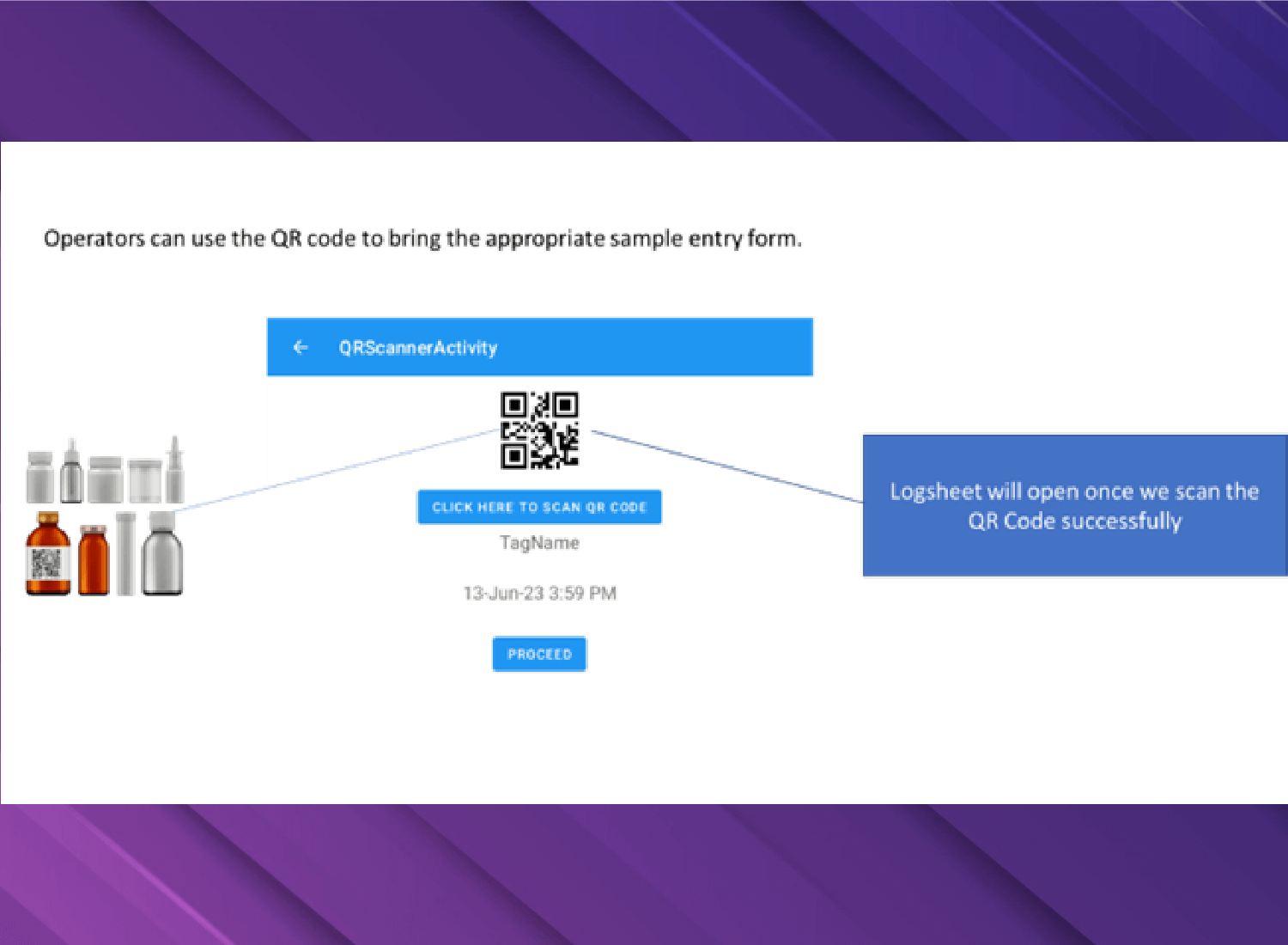

- QR scanning for faster data capture

- Seamlessly generate and download test certificates

- Enhance documentation efficiency

- Predefined workflows for scheduling and prioritizing samples

- Optimize lab technician workload and equipment use

- Automated reminders for calibration schedules

- Ensure equipment accuracy and compliance

- Ensure data integrity with role-based controls

- Comprehensive audit trails for transparency and compliance

- Identify and address quality deviations

- Link process parameters with RCA functionality

- Gain insights with built-in reports.

- Histograms and Cp,Cpk

- Predict future results based on historical data

- Correlate Process and quality parameters

- Proactive quality control and planning

How it works

LIMS can be seamlessly integrated with Historian and Performance Modules. The system ensures data integrity by providing the data validation, review and approvals accordingly. The system connects seamlessly with various analytical instruments, balances, and other plant instrument to automate data acquisition and eliminate manual transcription errors. It can manage and track batch testing with automated data capture from analytical instruments and implement real-time analysis of raw materials, finished products, and intermediate stages.

The Laboratory Information Management System integrates with existing production planning, ERP, and quality management systems for a holistic view of operations and facilitate closed-loop feedback, adapting to new and old models, facilitating standardized procedures and practices across diverse teams. The LIMS can also import instrument result files and use extracted data for quality control assessment.

A modular solution