Location: India

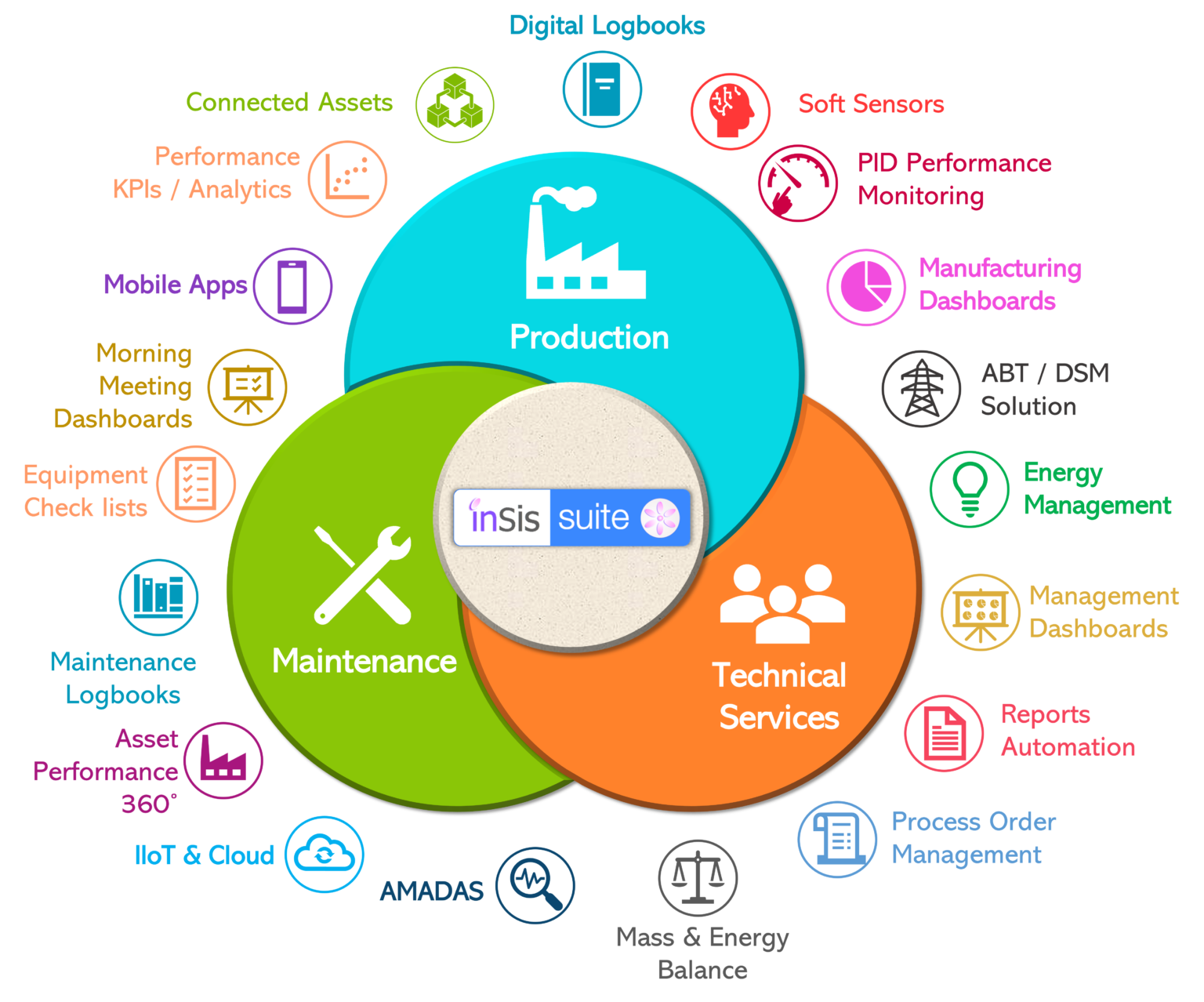

Asset Performance 360°

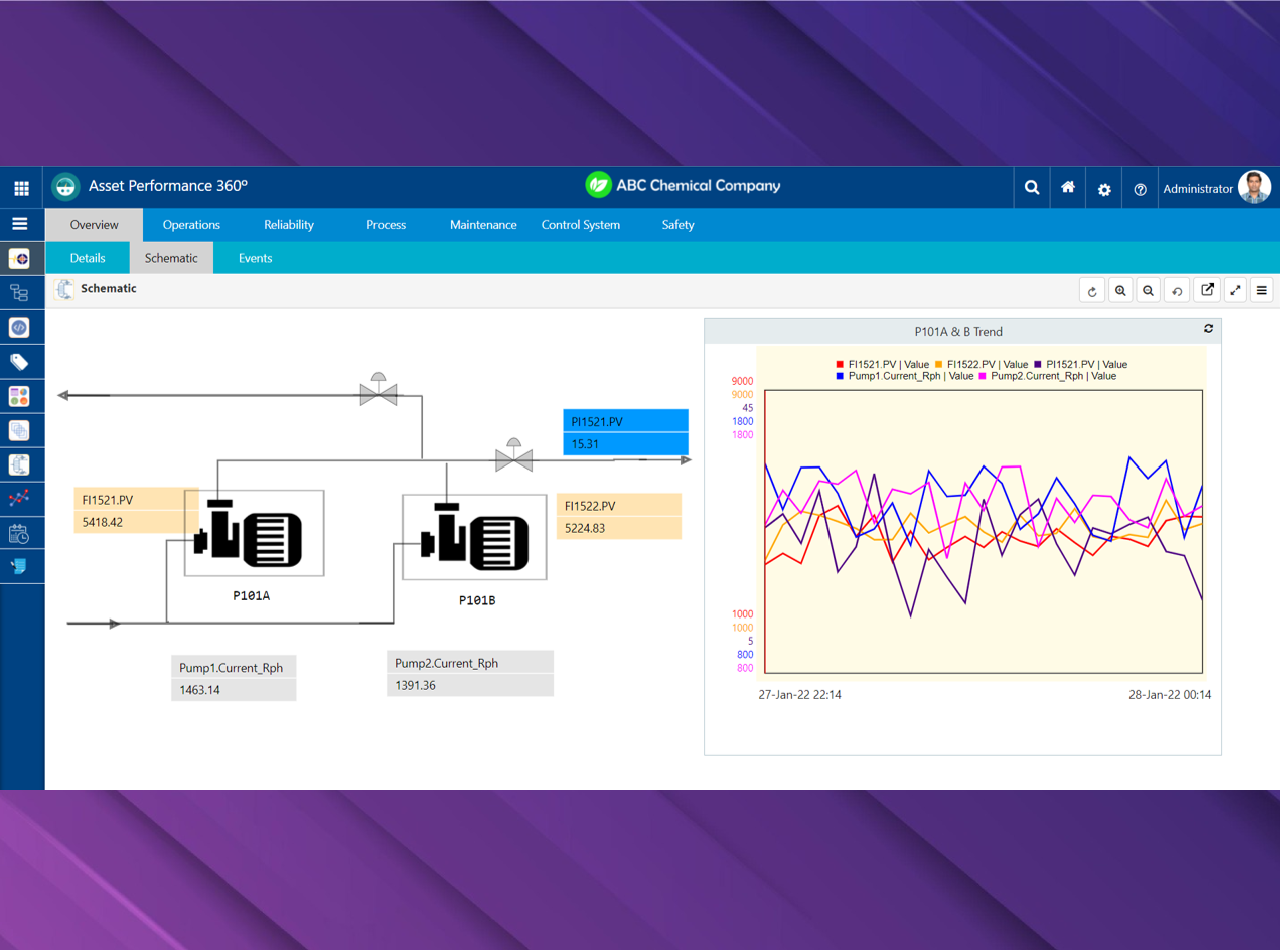

360° asset views, enhanced visibility

Solution benefits

Once you utilize our Asset Performance 360°, you will appreciate the importance of having a comprehensive platform to capture end-to-end view of assets.

Savings in data handling time

Accurate & timely data

Lesser troubleshooting time

How this helps your operations

Industrial project

Digital Logbook installed at a leading refinery

The project comprised of around 100 logbooks configured and implemented on more than 60 hand-held devices. The solutions was Integrated with client’s existing Historian & other MES systems, covering around 15 units. Both manual & automated data capture was implemented.

Core features

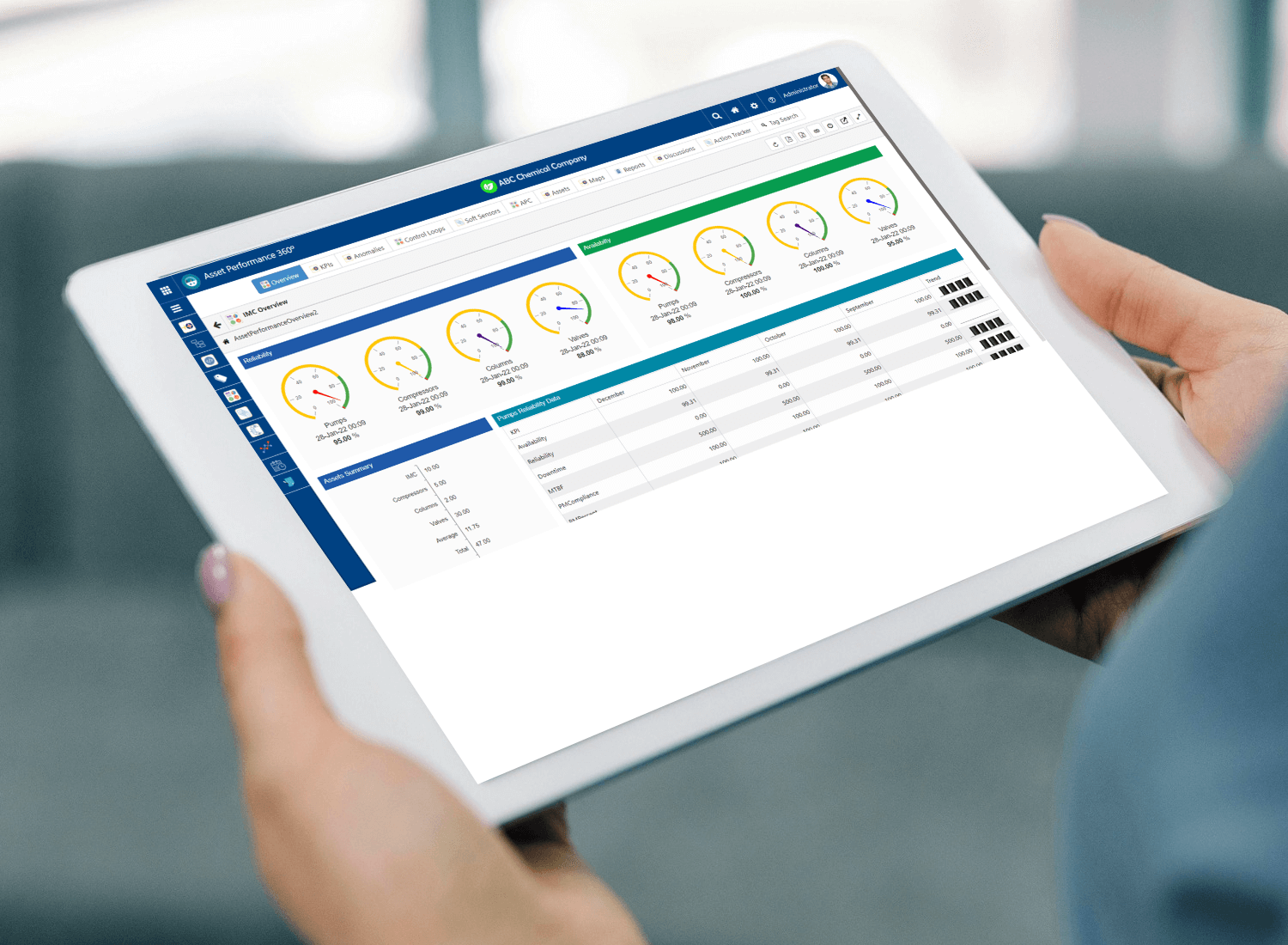

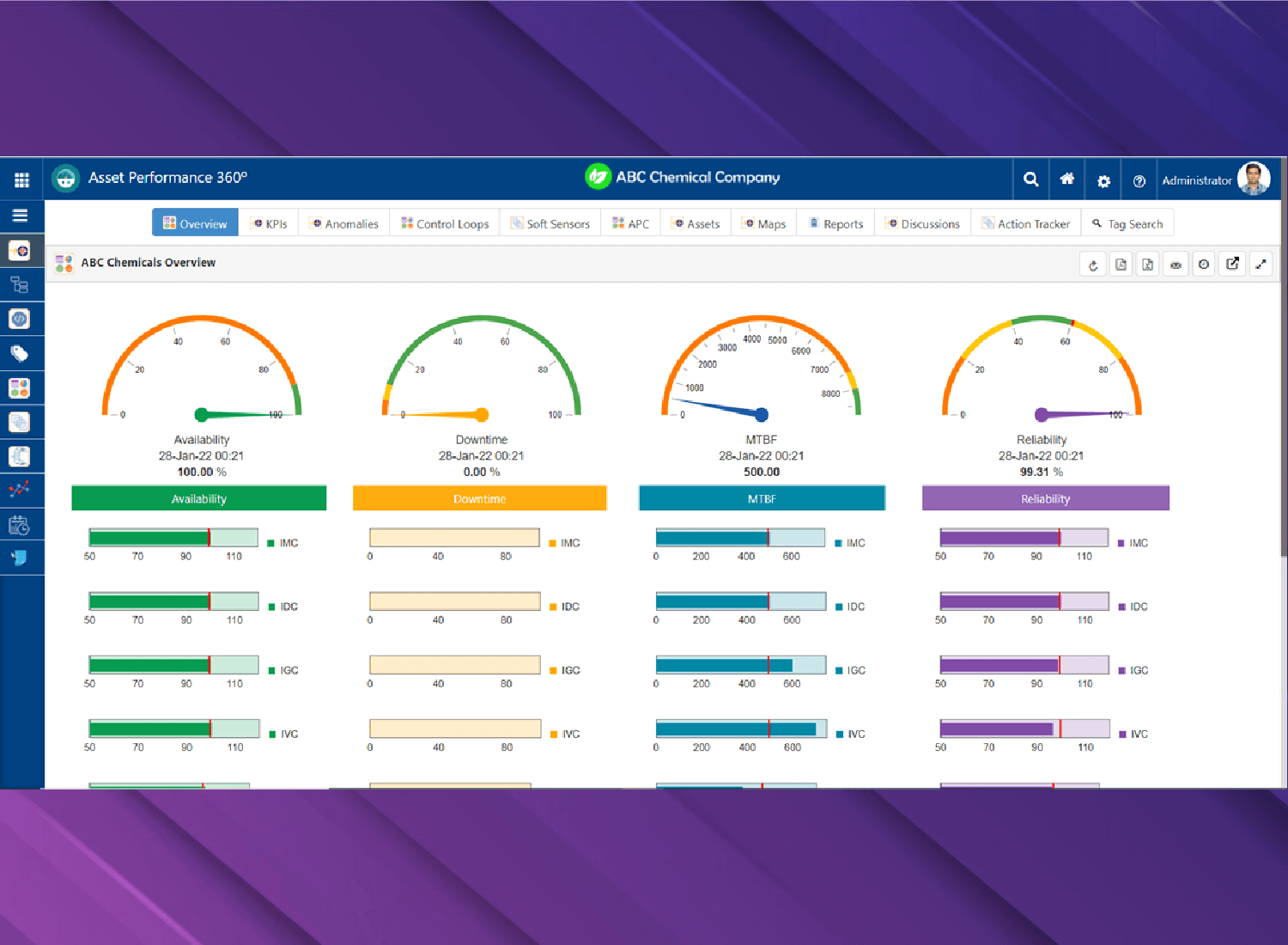

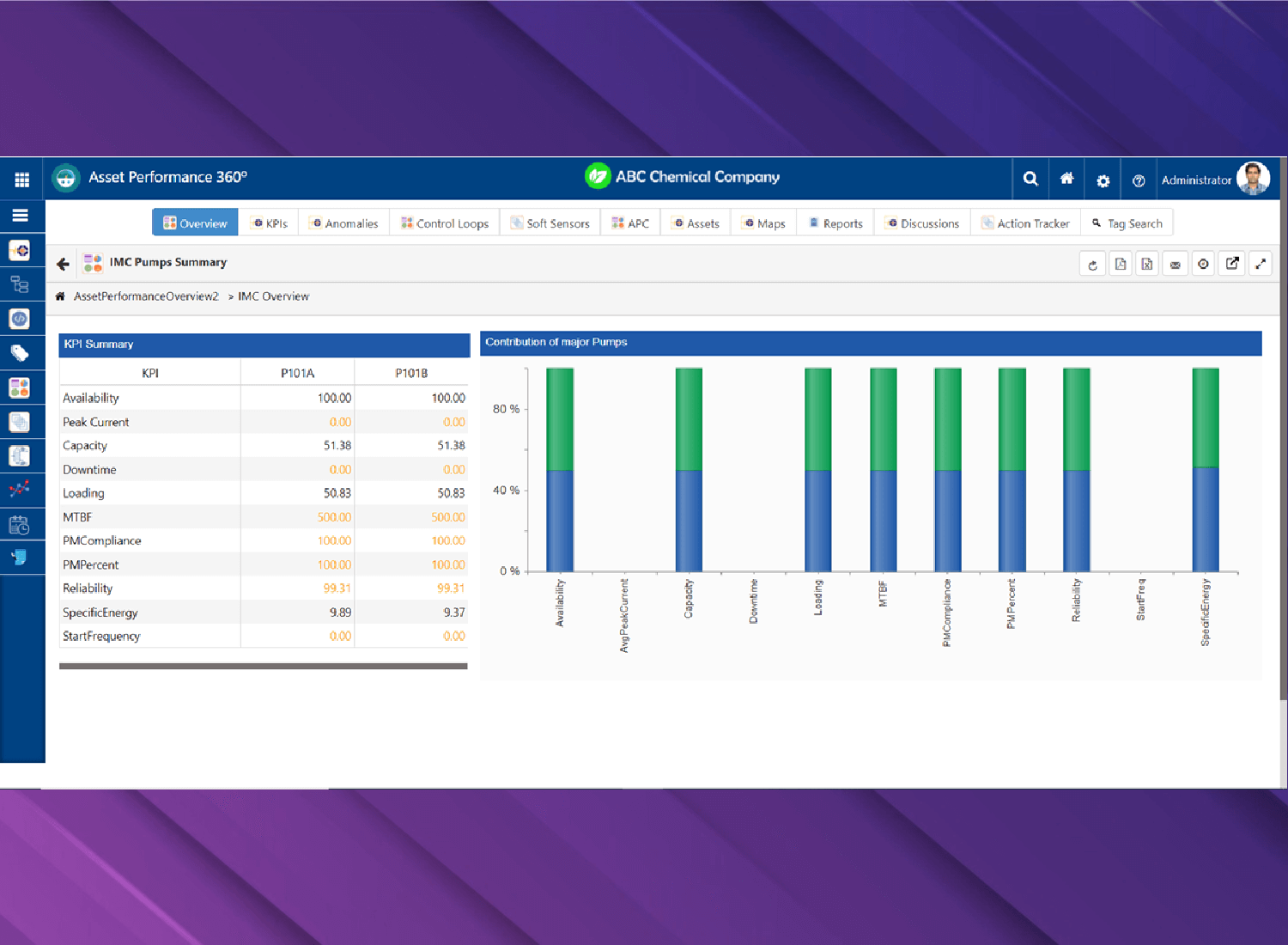

In this solution, asset KPIs, alerts, anomalies and reports are unified, with the capability to drill down to the finest asset level, thereby allowing effective management of assets.

- It allows you to minimize unplanned shutdowns through condition-based maintenance

- It helps in reducing the maintenance costs

- Early detection of potential problems minimizes repairs that can take equipment offline for extended periods

- By minimizing unplanned shutdowns and repairs, Asset Performance 360 helps you reduce downtime and keep your production lines running efficiently

- The system allows you to create detailed profiles for each asset

The Asset Performance 360° allows you to enhance the overall performance of your assets through simplified root cause analysis and easy identification of anomalies.

- Gain a comprehensive understanding of asset utilization patterns

- Allows you to optimize maintenance schedules, resource allocation, and overall asset management strategies for peak efficiency

- By identifying and resolving issues efficiently, helps you minimize downtime and keep your assets operational for extended periods

- Minimizes time consumption by automating tasks and simplifying root cause analysis, freeing up valuable time for strategic decision-making

This software increases the reliability and predictability of all the assets through the use of advanced analytics.

- Combined view of asset performance data and preventive maintenance data

- Quick and real-time calculations, providing immediate insights into asset health and potential issues

- Live asset health profiling through continuous monitoring

- Historical performance trend analysis of asset to gain valuable insights into degradation patterns and predict future maintenance needs

Maintaining peak asset performance is crucial for industrial operations, but reactive maintenance can be costly and disruptive. Asset Performance 360° steps in with its innovative Preventive Maintenance (PM) compliance feature, transforming your approach from reactive to proactive.

- Streamlines the entire preventive maintenance process

- Ensures your assets are serviced according to manufacturer recommendations

- Simplifies task management

- Optimizes maintenance resources and maximizes asset lifespan

This product enhances your decision-making capability through an automated alert system that allows real-time detection of abnormal conditions.

- Gain instant clarity with a rich library of over 30 visualizations tailored to specific user roles

- Effortlessly create custom dashboards and reports with intuitive drag-and-drop functionality

- By providing real-time insights, automated alerts, and clear visualizations, it significantly reduces the time required to make informed decisions regarding asset management

This software enables you to combine and harmonise data from multiple sources.

- Industrial Control Systems – DCS, PLC, SCADA systems for real-time process data

- Enterprise Systems – Integration with SQL databases like Oracle and SAP allows for historical data and contextual information

- Sensor Networks – Direct connection to L0/L1 sensors for capturing granular process details

- Flexible File Support – Import data from spreadsheets (XLSX), flat files, and CSV formats for even greater versatility

How it works

The Asset Performance 360° is a comprehensive tool that helps organizations track, monitor, and optimize their critical assets throughout their lifecycle. The system maintains a centralized database of all critical assets by integrating data from various sources. This data includes both live status and historical trends of every parameter of all the critical assets. It provides health profiles of various assets; anomaly detection for easy Root Cause Analysis (RCA), and leverages comparative scenario analysis for data-driven, decisive action.

The solution not only provides a birds-eye view of the plant operations in its entirety but also allows you to drill down to the second (unit) level, third (asset group) level, and fourth (asset) level details. The solution also carries out performance management with various KPIs, alerts and notifications, anomalies, reports, and dashboards.

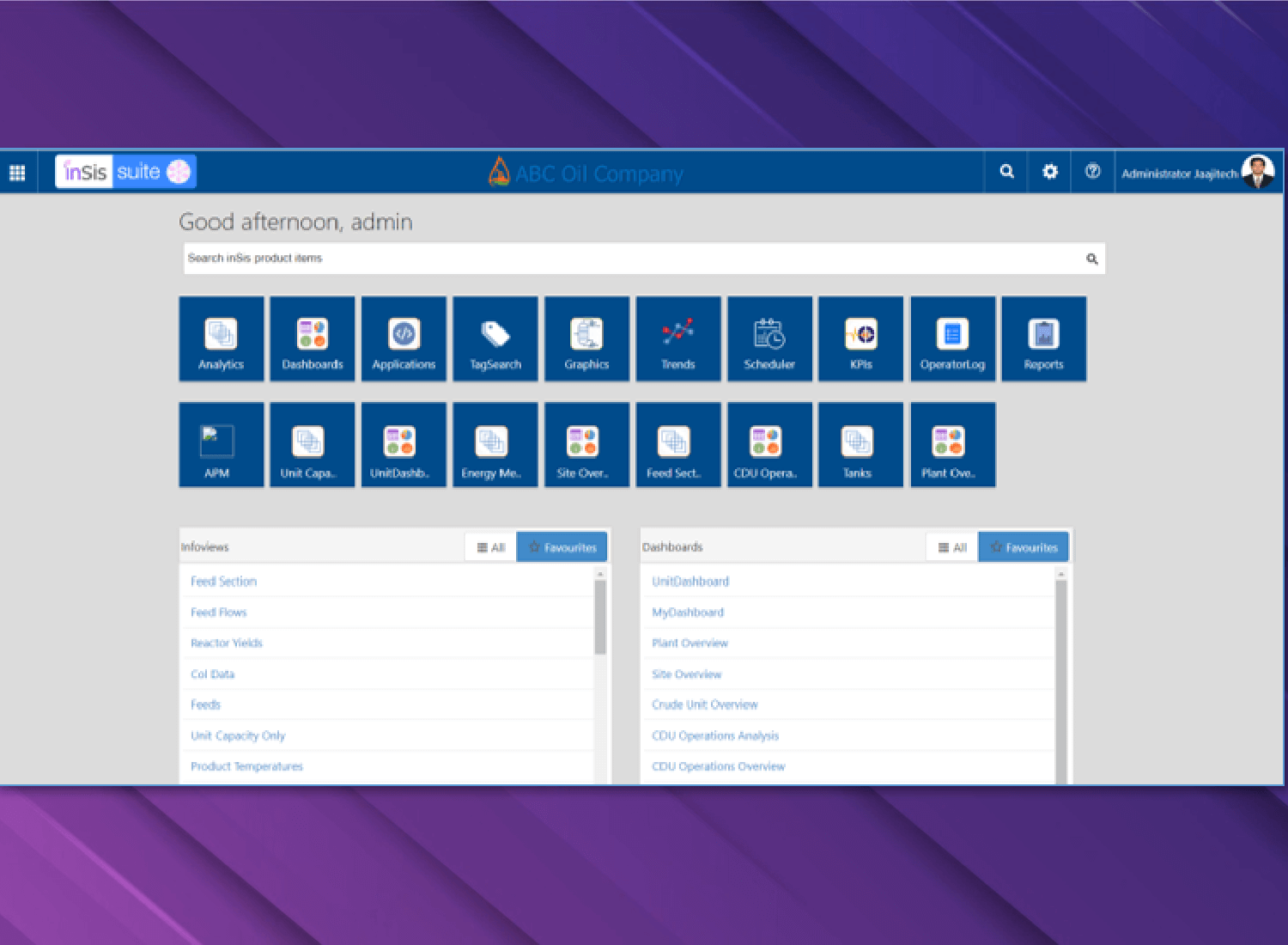

A modular solution

Resources

Deployment of Operations Logbooks in a Refinery on Hand-held Devices

Logbooks installed at a leading refinery – The project comprised of around 100 logbooks configured

Remote Monitoring of Pressure & Temperature of Oil-Wells in Real-time

We developed a POC for Remote Oil Well Monitoring, which offers real-time data with greater