inSis.AI

Overview

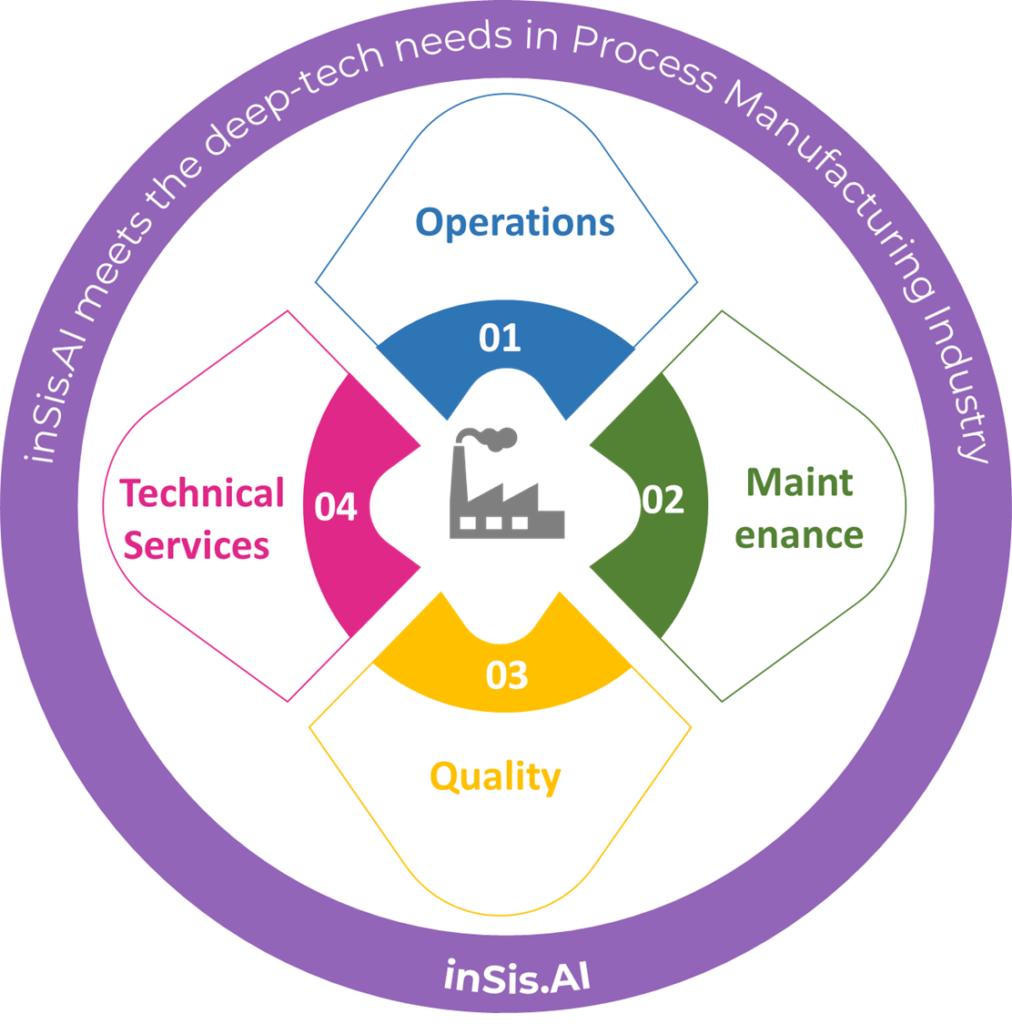

inSis.AI is the wrapper built on top of various inSis modules to help the end users analyze and predict critical parameters using various AI/ML techniques like NLP, PCA, ANN, SVM etc. It is a platform specifically designed to meet the evolving technical requirements of the process manufacturing sector, making use of an in-house developed Small Language Model that leverages NLP and Generative AI technologies. It offers several key modules, each addressing specific needs of the industry.

Quality

Real-time quality predictions to prevent off-spec products.

Reliability

Early warnings of anomalies developing in critical assets to avoid breakdowns.

Profitability

Optimal operating parameters to maximize profitability.

Productivity

Improved productivity with AI-assisted summary reports & analytics

Key Challenges Addressed

Real-time Product Quality Information

Ability to predict real-time quality metrics, like pH levels, before lab measurements.

Asset Anomaly

& Failure Detection

Detecting early signs of equipment failures to avoid costly service interruptions.

Optimizing Operating

Parameters

Finding the most efficient operating conditions in real-time by dynamically adjusting settings.

Log Summarization & Issue Detection

Analyzing extensive operations logs, comments & activities to pinpoint potential issues.

A platform leveraging AI/ML for manufacturing

inSis.AI is a versatile platform designed to leverage AI, ML and Generative AI for a variety of applications in the process manufacturing industry. It offers the following key modules, each addressing specific needs, with advanced technologies.

PredIT

Functionality: Predicts anomalies and qualities using deep learning models and advanced pattern recognition. Identifies KPI deviations based on process models in real-time.

OptimizeIT

Functionality: Uses Artificial Intelligence and Machine Learning models to identify relationships between process variables and use it for optimisation of the process.

AskIT

Functionality: Provides a natural language interface for providing various plant information. Generative AI and NLP technologies assist users by summarizing information & context.

ControlIT

Functionality: Predicts future process trajectories with remarkable accuracy, enabling automated control of the process plant and significantly reducing the need for human intervention.

On Roadmap

Key Modules

PredIT provides early anomaly detection for assets through advanced pattern recognition. Leveraging sensor residuals, a common library, and probability calculations, PredIT generates APR-based predictions to identify anomalies and predict remaining life. To mitigate risk, PredIT delivers early warnings with accurate Remaining Time to Act (RTA) and Time to Failure (TTF), enabling proactive intervention.

PredIT offers real-time troubleshooting for KPI deviations. AI/ML models are built for each KPI, utilizing relevant input parameters. When a KPI falls outside of acceptable limits or drifts away from its target, these models pinpoint the most likely contributing variable, presenting this information in a Pareto chart. This provides operators and engineers with real-time assistance, enabling them to quickly understand and address the root cause of the deviation. For example, if a quality metric goes off-spec, PredIT identifies the underlying cause, providing detailed analytics and insights to facilitate prompt corrective action.

PredIT offers real-time prediction of key parameters and qualities using AI/ML models. By leveraging historical data, models are built for critical product qualities and key controlling parameters, such as diesel end point, reactor yield, furnace CO/CO2, and excess O2. These models are then deployed online for real-time execution, utilizing live data from DCS/PLC systems to generate predictions. The predicted data can even be written back to the DCS for closed-loop control and optimization.

OptimizeIT provides real-time guidance to operators for adjusting operating parameters. Using historical data, models are built for key performance indicators (KPIs) and used to predict KPI outcomes. These models’ gains and weights are then incorporated into a Linear Programming (LP) or Quadratic Programming (QP) optimization framework to determine the optimal conditions for KPI improvement. These optimized guidelines are then communicated back to the DCS, empowering operators to make informed adjustments to the plant. For example, in a power plant, OptimizeIT can identify which variables to increase or decrease to optimize boiler heat rate.

AskIT boosts team productivity by providing a natural language interface. The inSis AI Assistant offers a chatbot interface, enabling users to ask questions related to plant information, such as tags, current values, and analytics. Several generative AI-based use cases are already integrated within inSis Apps. This functionality increases team productivity and significantly reduces the time required to access critical information. (edited)

Industial Use-cases

Operations

- Soft Sensors to predict critical quality parameters

- Provide optimal process conditions for an increased yield

- Provide ChatBot for operator manuals

- Identity the root-cause for decrease in the furnace efficiency

Maintenance

- Estimate the time to clean Heat Exchangers

- Predict a pump failure

- Estimate remaining life of a catalyst

- Identify the Tube Leak in a boiler

- Identify an abnormal behaviour of an asset in advance

Safety & Asset integrity

- Identify operational scenarios to mitigate the risks in process safety

- Analyse leaking patterns in a heat exchanger or reactor

- Identify the corrosion patterns and alert with predicted TTF

Sustainability

- Estimate impact on environment due to change in process conditions

- Minimize the energy costs and contribute to the Net-Zero emissions

Solution Features

Core Capabilities

Technical Specifications

inSis.AI adds a value layer from the digital transformation powered by inSis Suite

inSis.AI and inSis Suite are seamlessly integrated. While inSis Suite powers the digital transfrmation with its array of solutions, inSis.AI adds a value layer combining predictability and generativity to further optimize the processes. This enhance digitalization, streamline processes, and improve data availability and quality. The system features a user-friendly interface for operators and engineers, providing real-time dashboards, alerts, and detailed reports.