Location: Gujarat, India

Digital Operations Logbooks

Digitalized data, actionable insights

Solution benefits

By using Digital Operations Logbooks, you will discover the value of having centralized, reliable and easy-to-access knowledge for your operations.

Savings in operator’s time

Pay-back period

Accurate reports

How this helps your operations

Industrial project

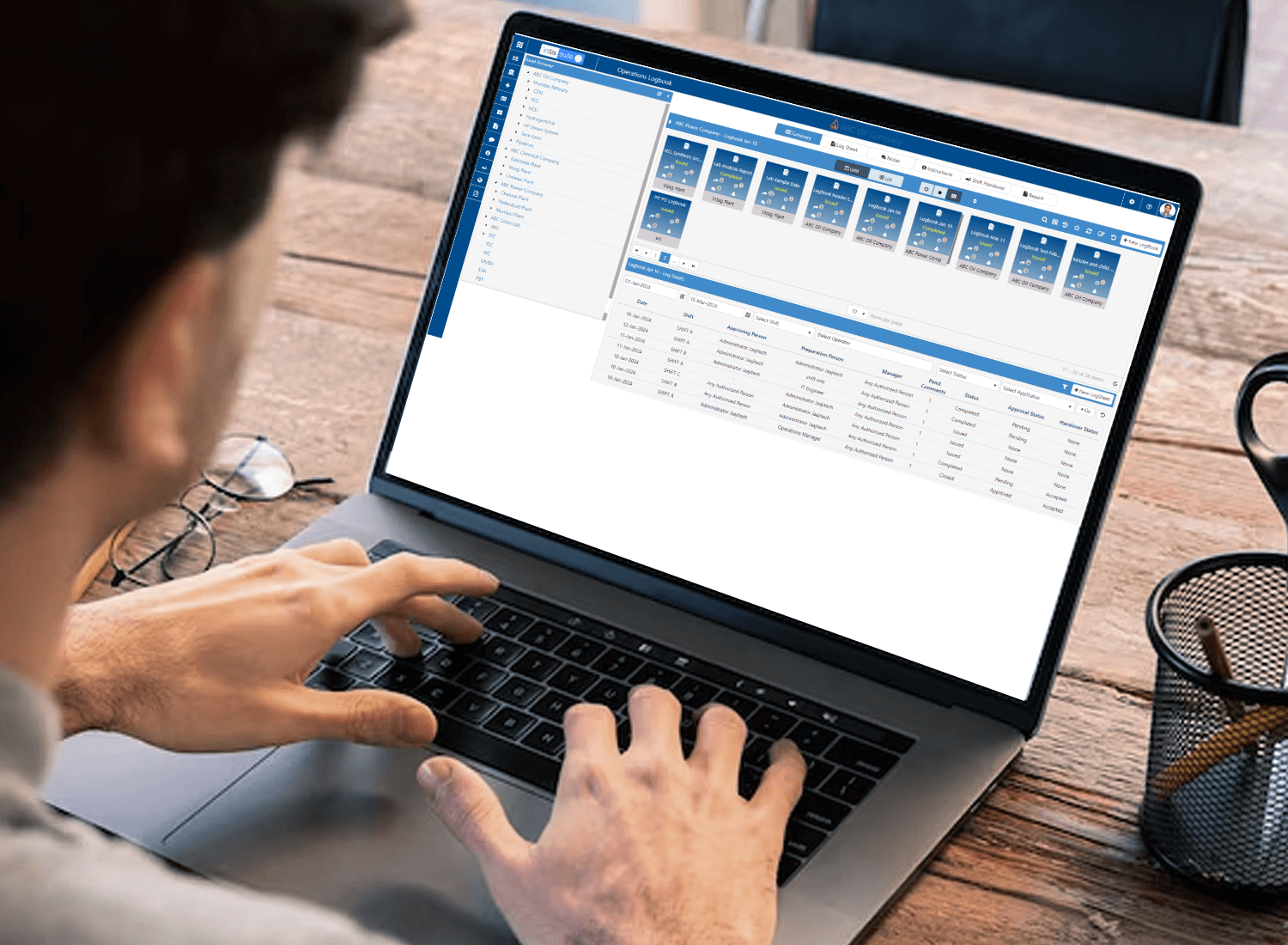

Logbooks installed at a leading refinery

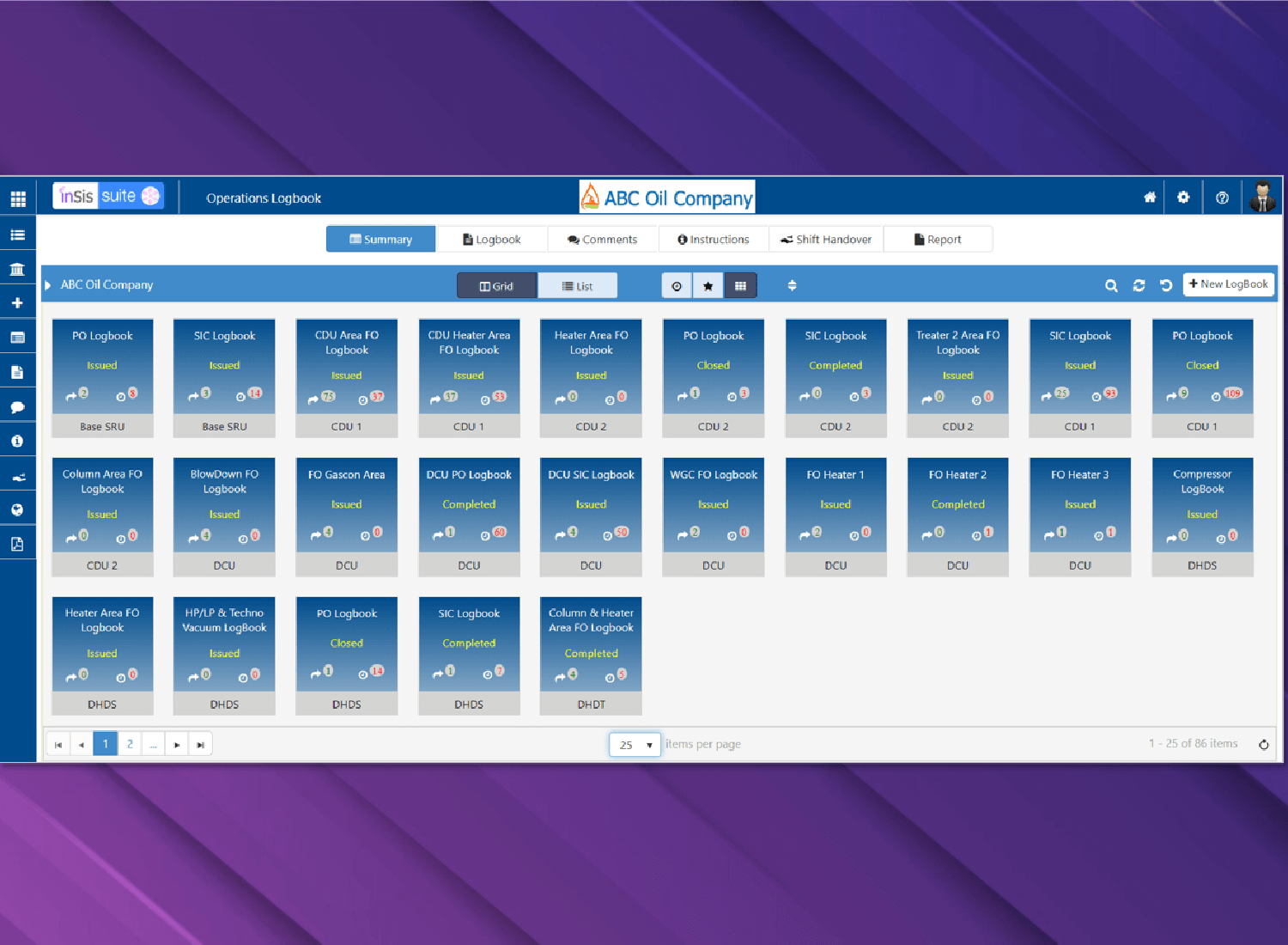

The project comprised of around 100 logbooks configured and implemented on more than 60 hand-held devices. The solutions was Integrated with client’s existing Historian & other MES systems, covering around 15 units. Both manual & automated data capture was implemented.

Core features

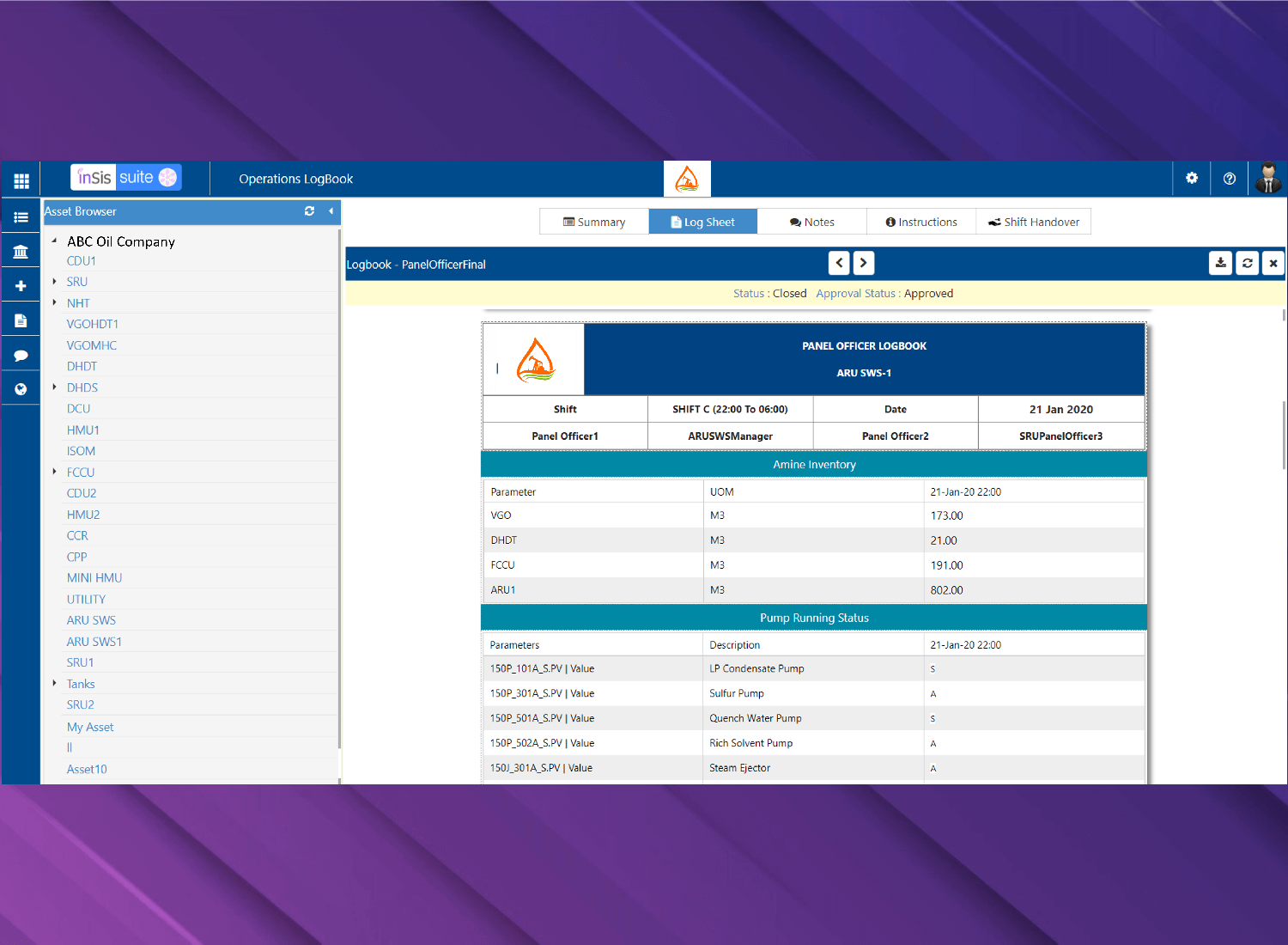

The digital operations logbooks collect, store, visualize, and analyze process information while allowing seamless integration with Interlock Bypass and Safe Limits Db.

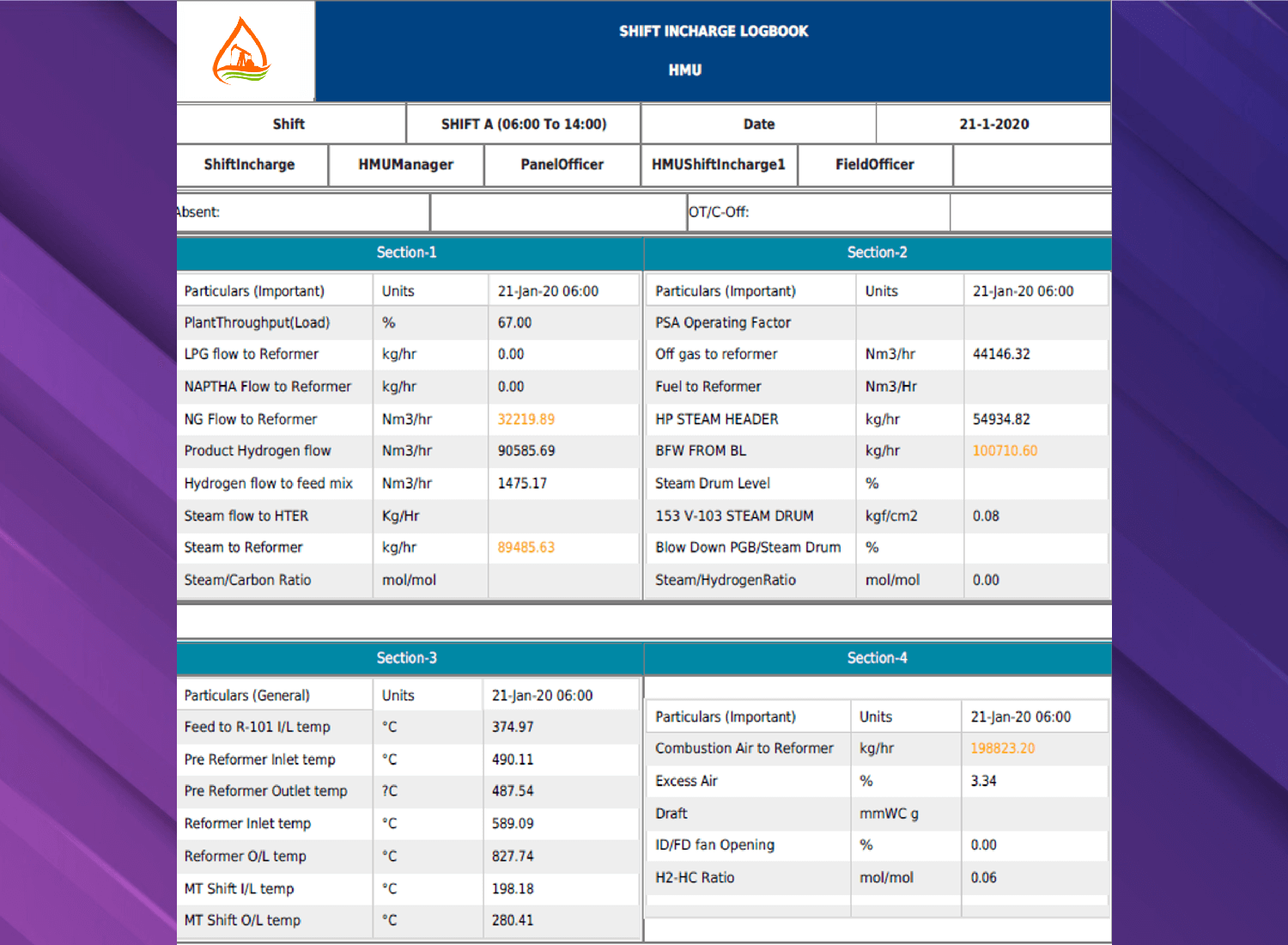

- Secure role-based management of logbooks with flexible layout, auto-filled logsheets and versioning, sharing and approval capabilities

- Summarization of information for the shift or day

- Generation of operator attendance report and comparison of logsheets, with deviation reports

These logbooks collect data from DCS, LIMS, EMS, TMS (Tank Farm Management System), SAP ( through RFCs) and provide data analytics, trends, dashboards, report and notifications.

- Connects to control systems and provide real-time visibility and trend of equipment operating data to operators

- Automatic synchronization of data from field logbook into Historian for immediate reference

- Optional auto-filling of log sheets for reviews, validations and updates

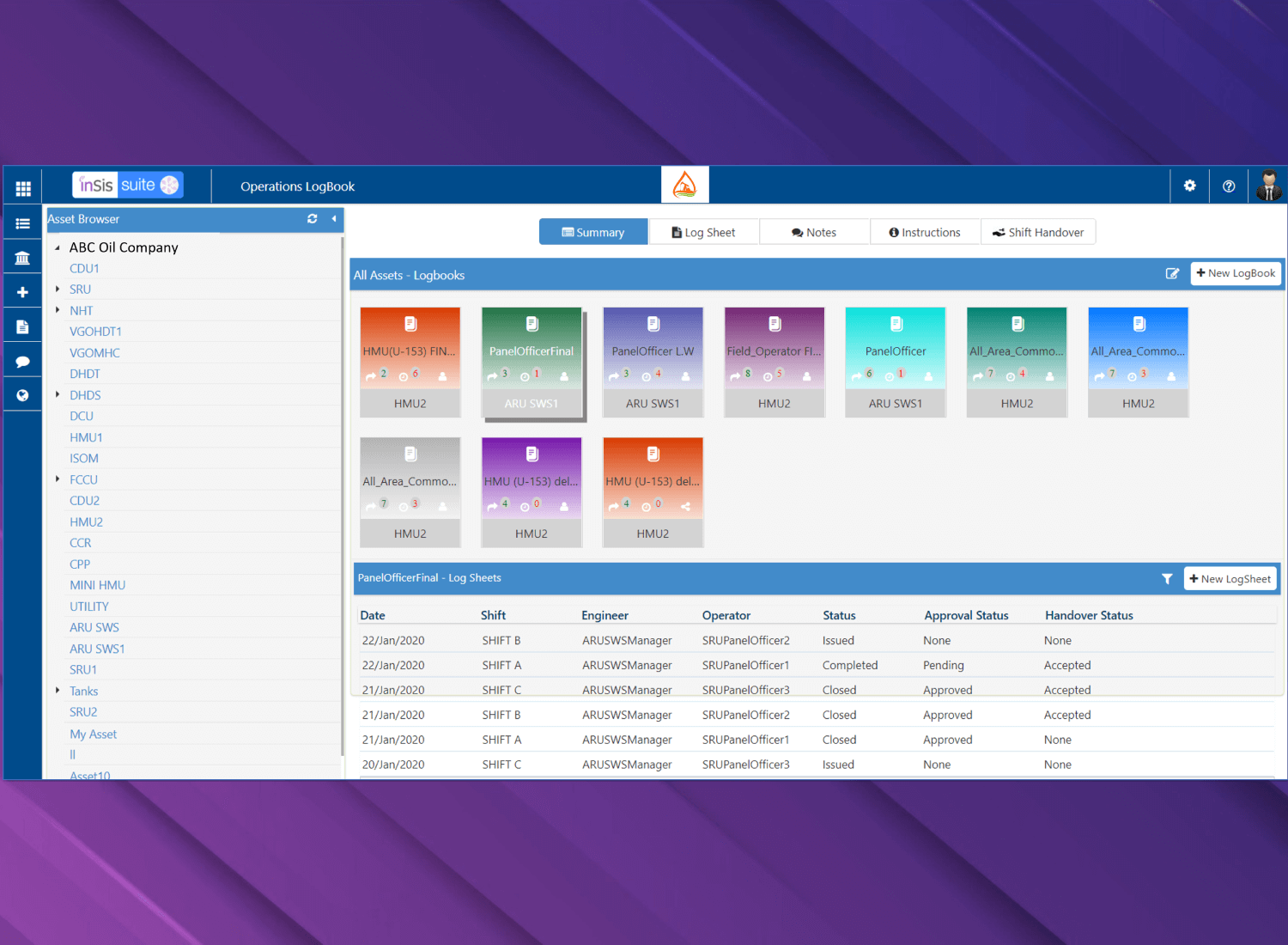

The logbooks review key points and minimize communication errors while carrying out effective and safe shift handovers.

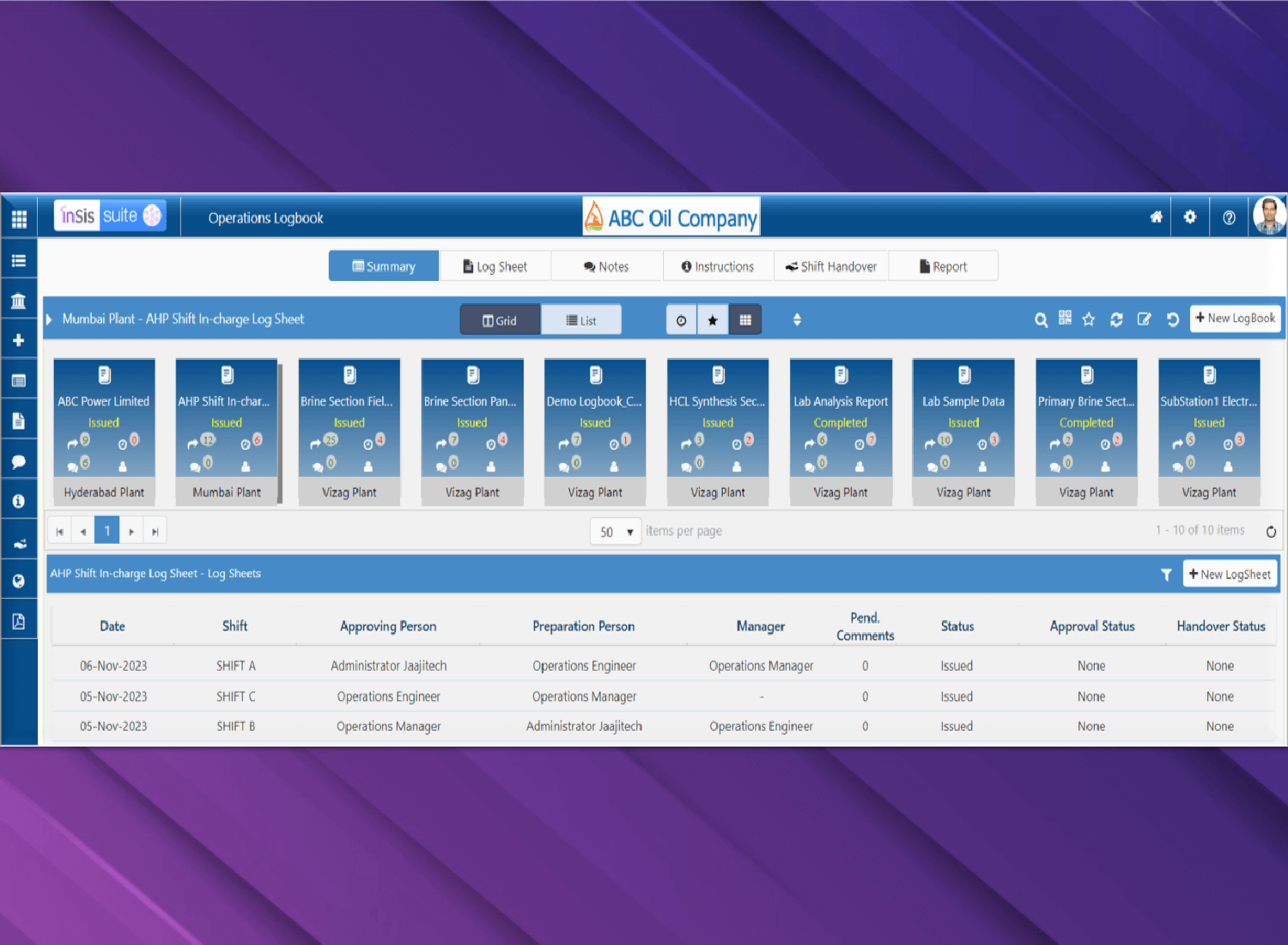

- Tracking of handover timestamps and outgoing and incoming operator information

- Capture of relevant information by the operator such as handover comments and log-sheet review status

- Approval workflow from operator to Shift engineer / In-charge

- Option for Shift-in-charge to reject a logbook with relevant comments

The digital operations logbooks ensure delegation of operational instructions to respective teams.

- Handles both temporary and permanent instructions

- Engineers/Managers can pass instructions to the operators and operators can acknowledge

- Tracks instructions until completion

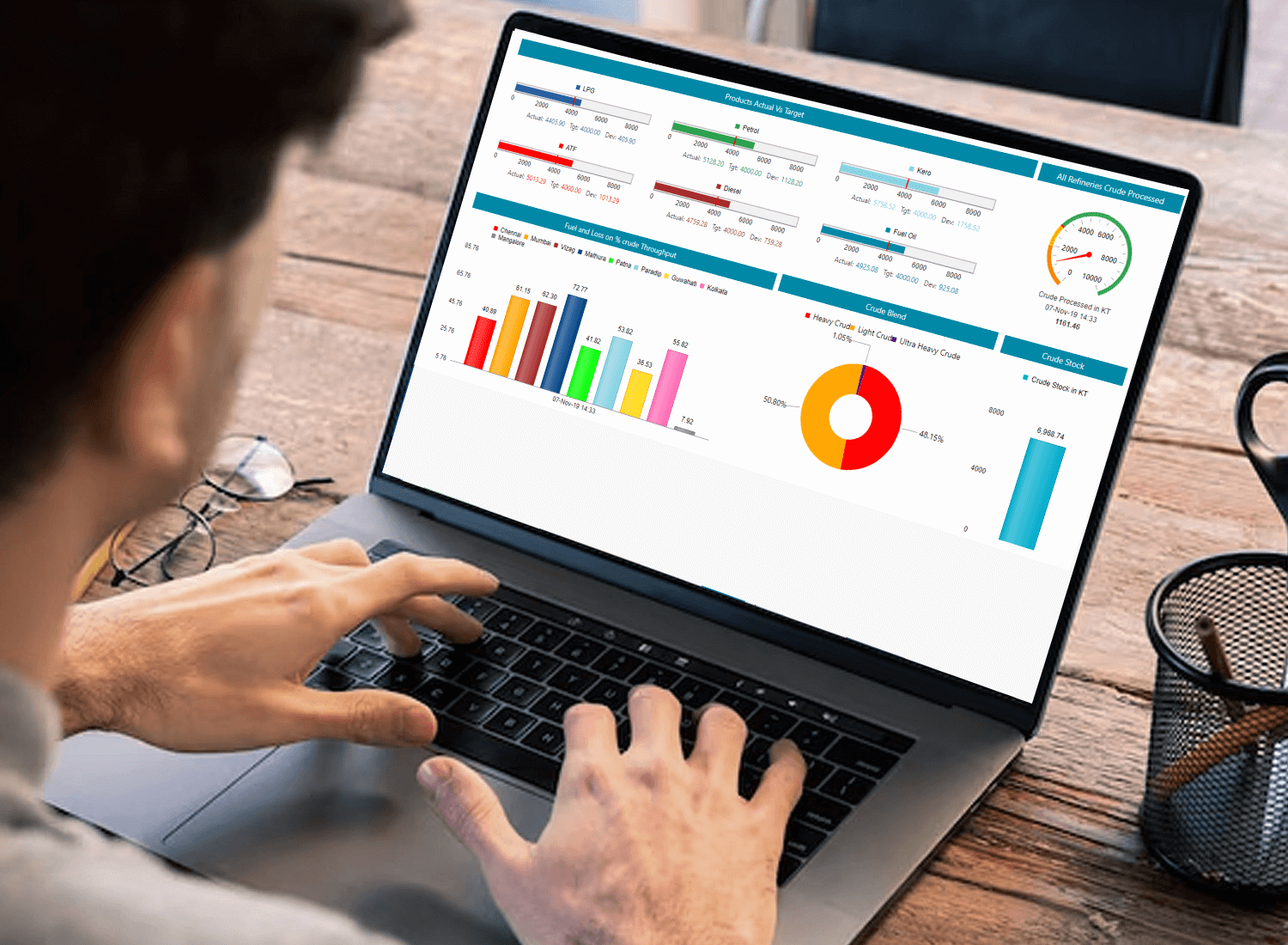

The data analytics capability of the digital operations logbooks helps you to analyze the data and gain meaningful insights for optimized operations.

- Realtime visibility of data, availability of historical data for analysis

- Self-configurable SmarTrend views

- Visualisation of critical information through charts and dashboards, notifications and reports

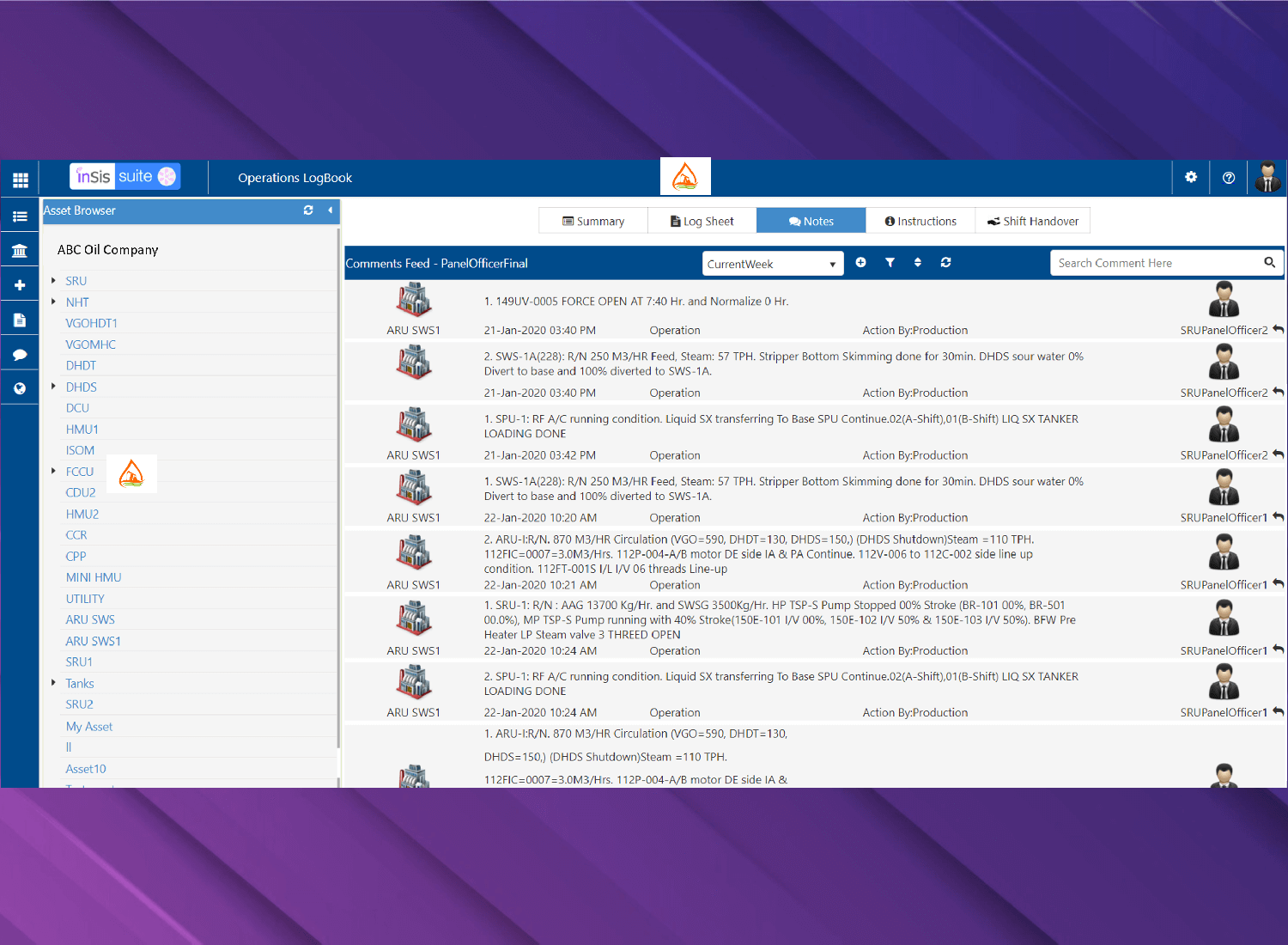

Apart from the human generated comments, the new advanced, AI based concise digital summaries provide enhanced operational efficiency, ensuring easy access to critical information and overcoming the traditional challenges of paper logbooks and manual summarization.

- Small Language Model leverages NLP and Generative AI technologies to summarize the comments from digital logbooks in a way that mirrors human summaries

- Operator can enter notes or comments against specific assets

- Simple, quick and easy management of comments at all levels with notifications and alerts

- Quick Search of comments by operator name, by asset name, by unit (between selected dates)

- Discussion style threads for effective response to the comments

How it works

• One of the key components of the digitization journey is data capture through the Digital Operations Logbooks.

• Data capture can be done in online, offline, or auto mode, as the situation demands.

• This data integrates with feeds from sources like DCS, Historian, SAP, LIMS, and MES, making it comprehensive and accurate for further analysis.

• The solution captures logsheet data, comments, instructions, activity details, critical information, and shift details. It also compares logsheets for scenario analysis.

• Additionally, it provides hourly, shift-wise, and daily summary views for different levels of stakeholders, highlighting trends, deviations, and anomalies with easily understandable reports, graphs, and charts.

• Apart from the human generated comments, the new advanced, Generative AI & NLP based concise digital summaries that mirror human comments, ensure timely access to critical information and helps in overcoming the traditional challenges of paper logbooks and manual summarization.

inSis Suite - A modular solution

Resources

Deployment of Operations Logbooks in a Refinery on Hand-held Devices

Logbooks installed at a leading refinery – The project comprised of around 100 logbooks configured

Monitoring & Calibration of Analysers for a Refinery through Yokogawa

The solution Analyser Management System (AMADAS) was designed for ERU/EG units of the refinery. It